Fusion 360: Integrated CAD, CAM and CAE Software.

As manufacturing changes, so should your tools.With Fusion 360 make quality parts faster, reduce cycle times and increase your bottom-line utilizing a single unified platform

What is Fusion 360?

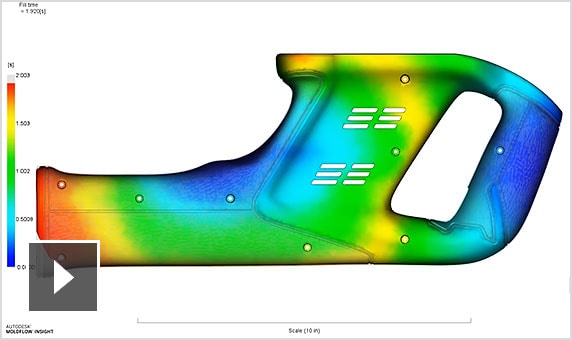

A multifaceted 3D CAD & 3D Printing software that enables you to design effortlessly. This all-rounder software allows designing, manufacturing, and machining capabilities within one single platform. Its integrated CAM, CAD and CAE interface avoids costly rework, defects, and missed deadlines that may impact your work. Its simulation tools help you test your 3D designs early in the development process to determine product performance and uncover costly flaws.

See how Fusion 360 works with

other Autodesk software

DISCONNECTED

PROCESSES

COMMUNICATION BREAKDOWN

MISSING

DEADLINES

Traditional CAD platforms are fragmented, expensive, and disconnected – causing costly inefficiencies and exacerbating challenges.

Disparate software breaks down communication, and if changes are needed to be made, can create significant extra work.

Poor communication either upstream or downstream can lead to slow feedback and mistakes. Working in silos can also hinder improvements in performance.

Finally lengthy programming times, setup times, or inefficient cycle times can all contribute to missing deadlines.

Features

3D Design & Modeling

Engineer products with a comprehensive set of modeling tools. Ensure form, fit, and function of your products with various analysis methods

Manufacturing

From high-efficiency roughing with Adaptive Clearing to simplified control of multi-axis machines with Tool Orientation,

Generative Design

Explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight, improving performance, and consolidating parts.

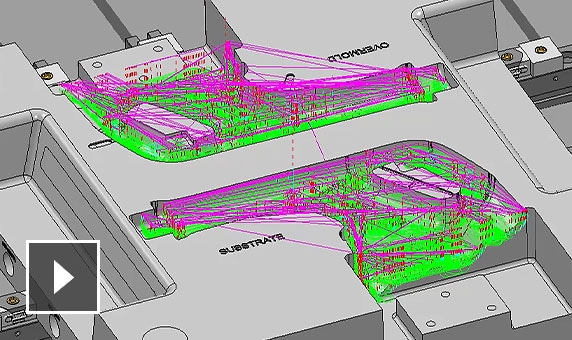

Data Management

Data management is the center of your unified development process. Gain more control by leveraging managed user permissions, version control, and cloud storage.

Additive Manufacturing

Quickly create physical prototypes to validate designs prior to manufacturing and build 3D printed parts using additive manufacturing in Fusion 360.

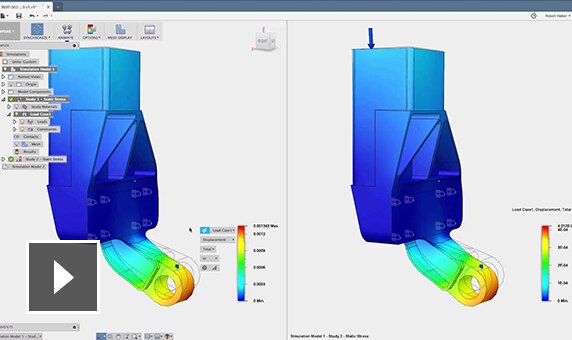

Simulation

Test your designs to ensure they will survive real world conditions. Simulate your products digitally, reducing the cost of prototyping by using fully-validated solvers.

Dan Ko

Strategic Initiatives Lead | Shapeways

“If we didn’t have Netfabb to automate a large portion of the file preparation process, each build would be substantially more time consuming and labor intensive.”

Sean Buxton

Senior Mechanical Engineer, Ximedica

"One of the most exciting things about the Form 3 is where the low force print process brings us in terms of print quality and finishing. We’re excited about how we can push the limits of, particularly really tiny features. I am amazed at the small details that show up in models. It's really impressive."

Connect With A Fusion 360 Expert