PowerShape® helps engineers to quickly import, repair and prepare complex models for manufacture

Create complex geometry to better control CAM software.

What is Powershape?

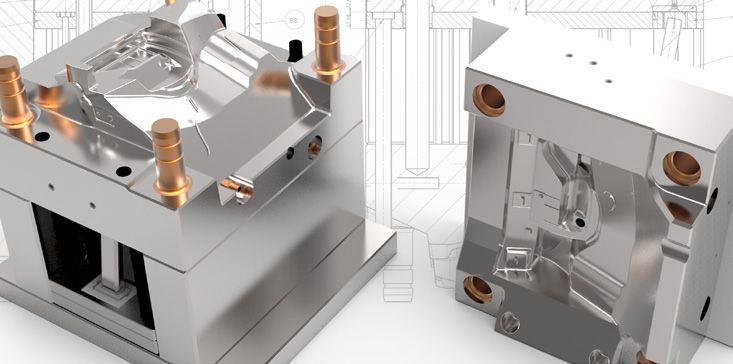

Fusion 360 with PowerShape® manufacturing CAD software combines surface, solid, and mesh modeling to help prepare molds, dies, and other complex parts for manufacture. Includes access to Fusion 360 and Fusion 360 Team.

Core and cavity splitting

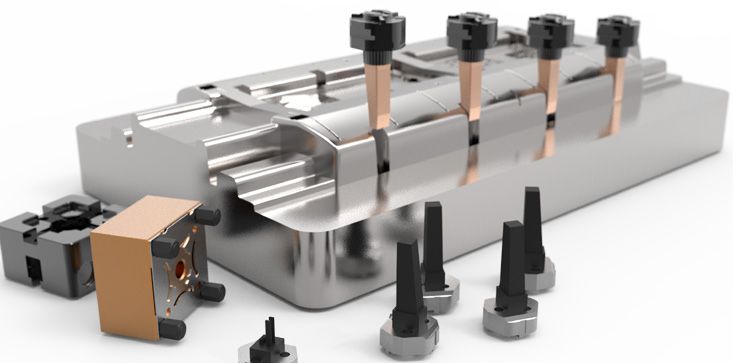

Electrode design and manufacture

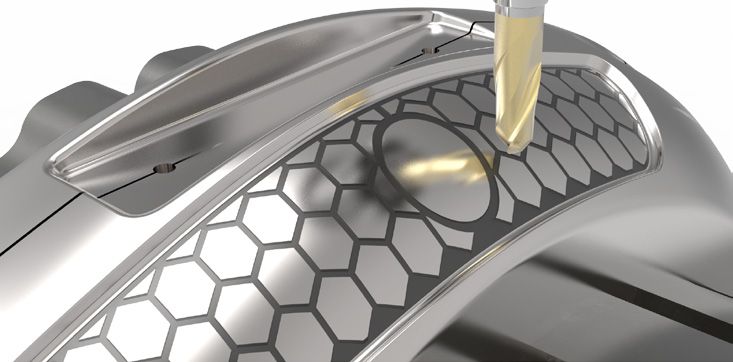

Automated rib capping for EDM

Work faster with focused modeling for manufacture tools

Access wizards in PowerShape to automate common modeling tasks. Quickly convert product designs into molds, tools, and dies ready for CNC machining.

10 reasons to choose PowerShape

Modeling for manufacture

High volume, production parts are usually created by molding, casting or forging, all of which require the manufacture of some kind of mold, tool or die. Creating these, “modeling for manufacture” is where PowerShape excels.

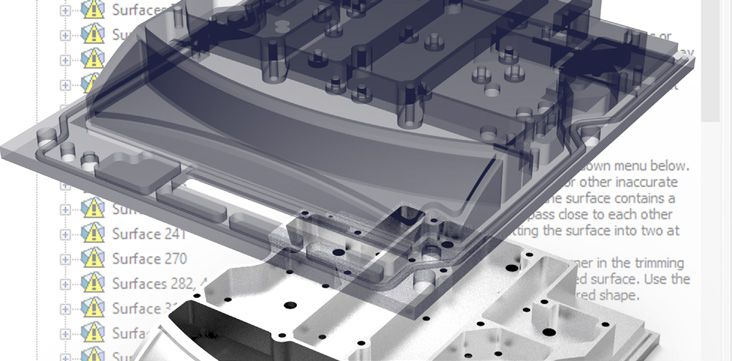

Model analysis Import models from all mainstream design systems. Use analysis tools to quickly identify faults that could complicate downstream manufacturing processes, such as:

Features

Model Repair

Use automated wizards to help find and fix critical faults that could negatively impact CAM programming. Help reduce wasted modeling time by identifying and ignoring insignificant faults to allow CNC machining to begin sooner.

Replace corrupted regions of the model with smooth, tangent fill-in surfaces or use powerful trim region editing to fix individual faces.

Use direct modeling to edit parts without the need for a solid model history.

Tool and Die

Use modeling tools designed to meet the needs of mold, tool and die manufacturers. Interactively find more optimal line-of-draw to ensure tooling is more cost effective.

Quickly produce complex split lines, shutout faces and convert designs into core and cavity halves. Identify undercut features and produce 3D sliding cores and lifters.

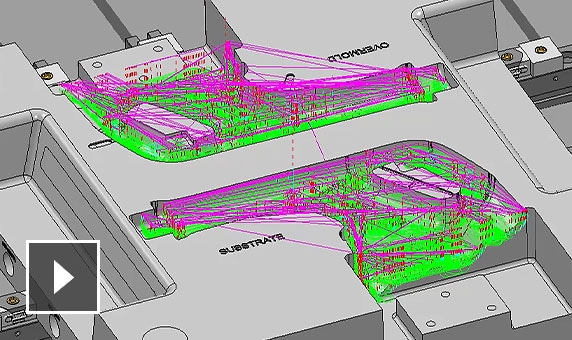

Automated EDM electrode design, make and use

Access a suite of modeling tools for the design, manufacture, inspection, and utilization of electrodes for EDM.

Quickly extract burn regions and combine with holders from major suppliers. Output data to PowerMill for automated toolpath generation. Export scripts and macros to your shop-floor EDM hardware for more efficient datum setup and burning.

Your Cam Campanion

PowerShape is the ideal modeling companion to use alongside PowerMill® and FeatureCAM®. Create additional geometry to help with CAM programming.

Sketch wireframe boundaries to control the extents of machining. Automatically produce capping surfaces that smoothly cover ribs and other features that will be produced with other manufacturing processes such as EDM.

Construct curves and surfaces to more precisely control the motion of 5-axis machines and industrial robots.

See how PowerShape works with

other Autodesk software

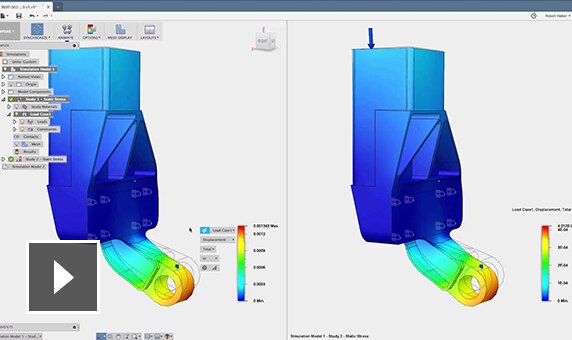

PowerShape + Fusion 360

Verify your PowerShape designs with mechanical and thermal simulation.

PowerShape + PowerMill

Rapidly create 3- and 5-axis toolpaths, and optimize NC programs for use on CNC machines.

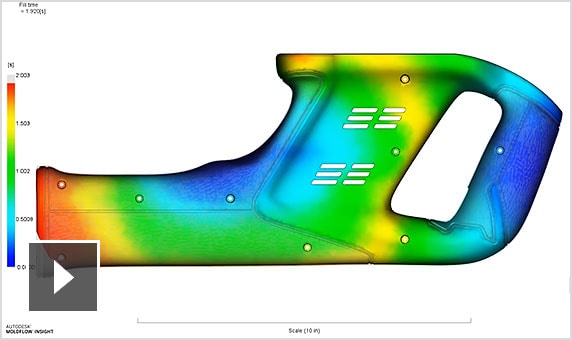

PowerShape + Moldflow

Create, simulate, and optimize tooling design to produce more accurate and complex molds.

“The interaction between PowerMill and PowerShape has definitely streamlined our ability to manufacture molds. We can start making chips right away.”

SHAWN MCNAMARA,

DESIGNER, CHICAGO MOLD ENGINEERING

Connect With A Powershape Expert