No products in the cart.

Small Details,

Huge Results

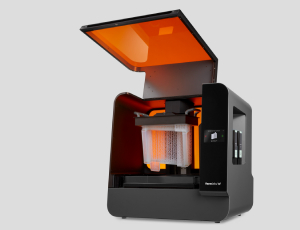

Eliminate the turnaround time of outsourcing or the manual work in assembling for large scale 3D prints. The Form 3L offers a massive build volume at an unparalleled value.

Incredible Part Quality

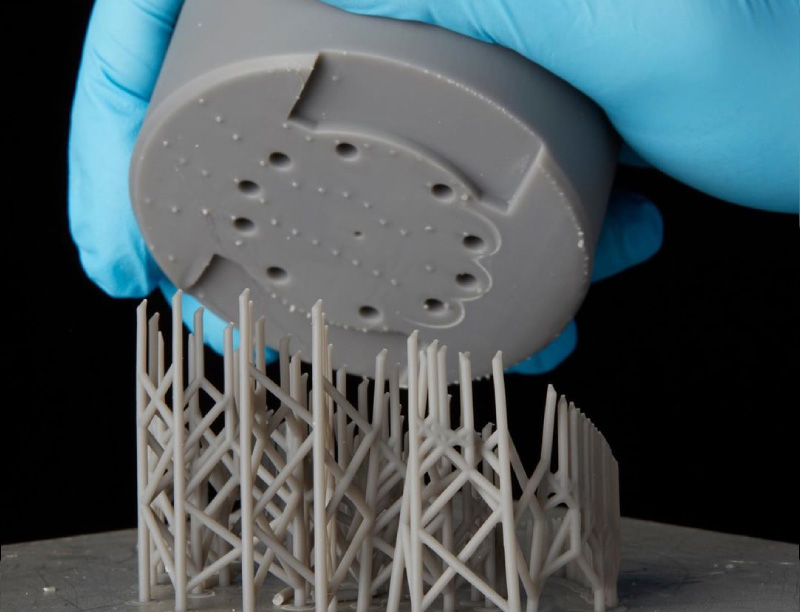

No longer sacrifice quality for larger prints. The Form 3L provides incredible surface finish and fine detail that Stereolithography 3D printing is known for.

Low Force Stereolithography (LFS)™ uses a flexible tank and linear illumination to deliver groundbreaking print quality and printer reliability.

Optimized Laser Path

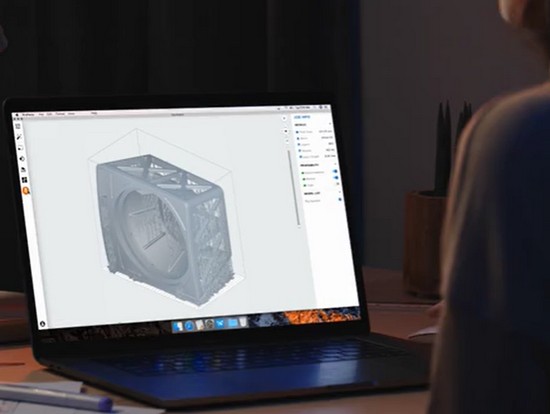

Two staggered Light Processing Units (LPUs) inside the printer use a compact system of lenses and mirrors to deliver accurate, repeatable prints.

Intuitive and Efficient

No specialized technicians required. The Form 3L offers automatic resin dispensing, simple print preparation software, and an interface that anyone at your company can use.

Nonstop Printing

Integrated sensors help maintain ideal print conditions and send you alerts about the state of your machine.

The Right Material for the Job

Work seamlessly within the Formlabs ecosystem of general purpose and specialty materials. The Form 3L can hold two easy-to-switch resin cartridges, preventing interruptions during large print jobs.

Perfectionism That Scales

With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process.

25μm |

|---|

335 × 200 × 300 mm Build Volume |

25 – 300μm |

Connect With A Formlabs Expert