No products in the cart.

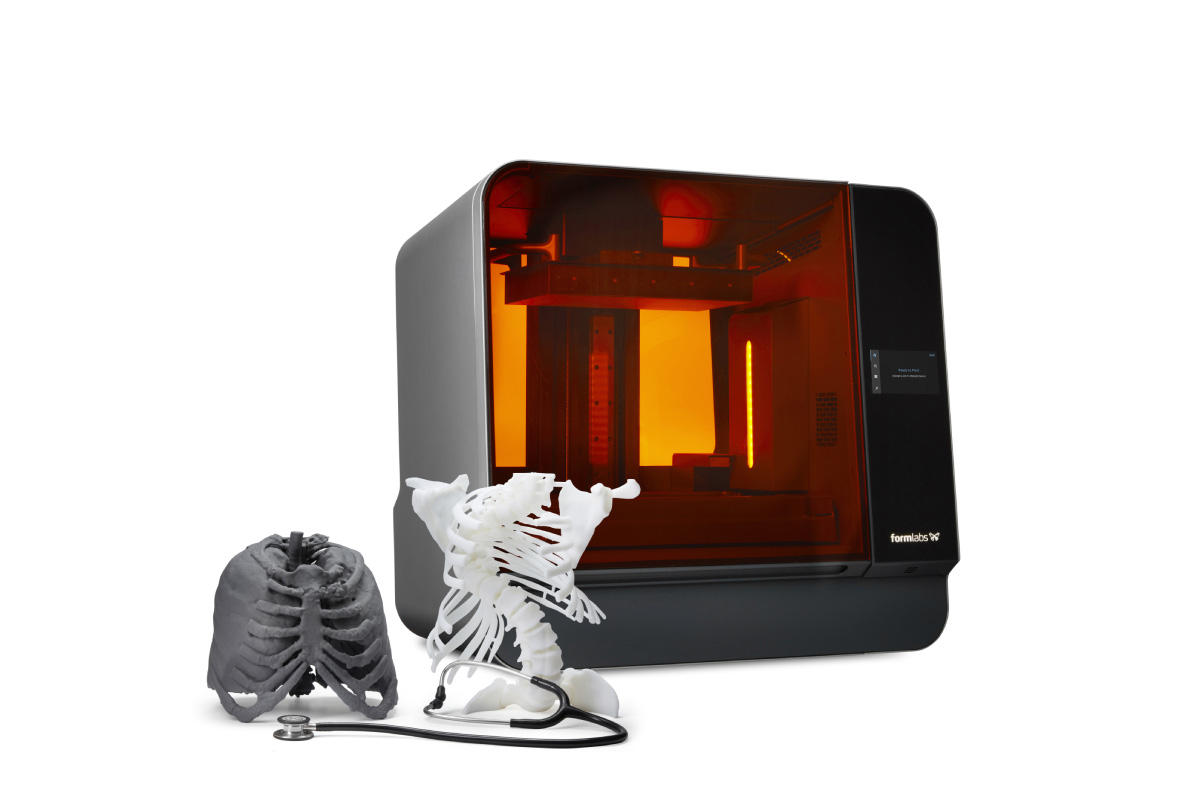

Fine Precision 3D Printer for Human-scale Customisation

Perfect for hospitals, universities, healthcare institutions and research labs, elevate patient-care innovation with Form 3BL’s seamless, on-demand printing capacities. Enable life-size anatomical models, customisable surgical tools, and medical devices offering scalable solutions. Start your journey today!

Gain an Exclusive Benefit.*

*Terms & Conditions apply

Fine Precision 3D Printer for Human-scale Customisation

Perfect for hospitals, universities, healthcare institutions and research labs, elevate patient-care innovation with Form 3BL’s seamless, on-demand printing capacities. Enable life-size anatomical models, customisable surgical tools, and medical devices offering scalable solutions. Start your journey today!

Gain an Exclusive Benefit.*

*Terms & Conditions apply

Committed To

Clinical innovation

Our technology has been validated in FDA-cleared workflows and we develop and manufacture our own materials in an ISO 13485 certified facility.

Incredible Part Quality

No longer sacrifice quality for larger prints. The Form 3BL provides incredible surface finish and fine detail that Stereolithography 3D printing is known for.

Low Force Stereolithography (LFS)™ uses a flexible tank and linear illumination to deliver groundbreaking print quality and printer reliability.

An End-To-End 3D Printing Ecosystem

We’ve made every step of the process as easy as possible, with simple print preparation software and our automated post-processing system, Form Wash and Form Cure.

Scales With You

Start with one 3D printer or many, and add capacity as demand grows or needs change. Get helpful, personal service when you need it from a Formlabs expert with our Medical Service Plan.

Nonstop Printing

Formlabs 3D printers constantly monitor print performance so you can focus on creative solutions. Many components can be replaced in-house, reducing the need for replacement printer shipments.

The Right Material for the Job

Work seamlessly within the Formlabs ecosystem of general purpose and specialty materials. The Form 3L can hold two easy-to-switch resin cartridges, preventing interruptions during large print jobs.

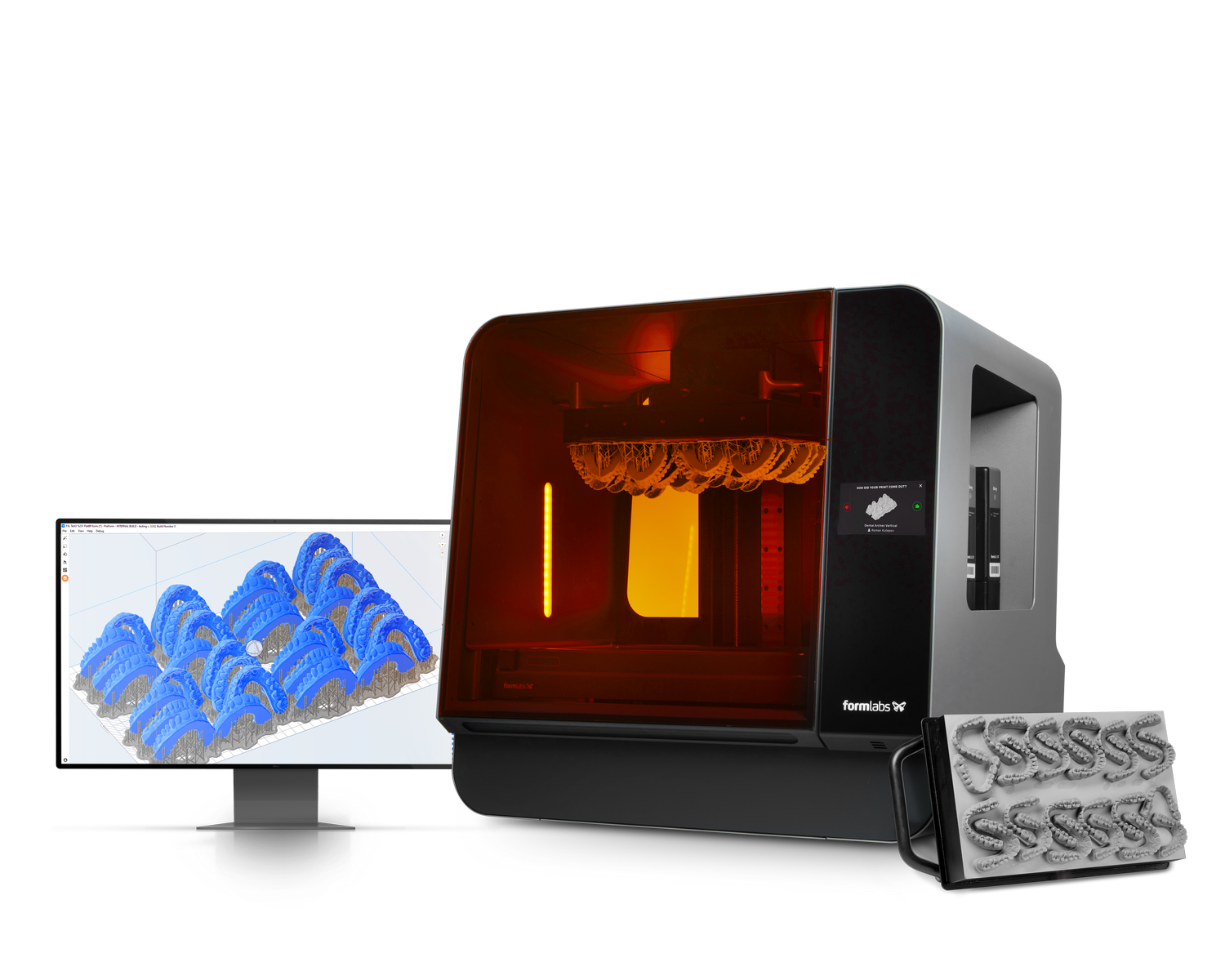

Perfectionism That Scales

With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process.

25μm |

|---|

33.5 × 20 × 30 cm Build Volume |

25 – 300μm |

Connect With A Formlabs Expert