No products in the cart.

Sign Up below

and get instant access to our product

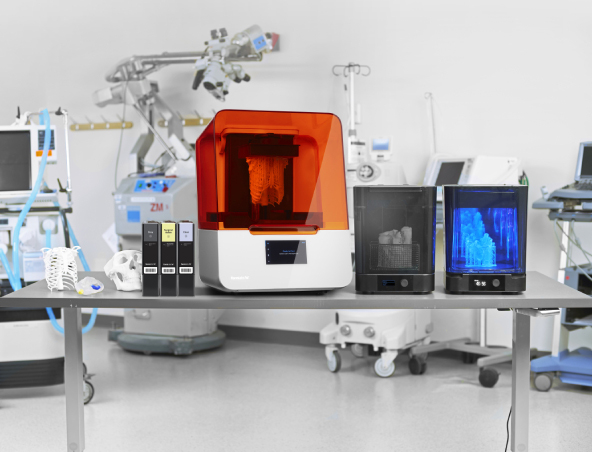

Advanced Low Force Stereolithography (LFS)™ technology uses a flexible resin tank and a custom-designed, user-replaceable Light Processing Unit (LPU) to produce consistent, accurate prints. Reduced peel forces lead to incredible surface finish and part clarity, right off the printer.

XY Resolution: 25 microns

Build Volume: 14.5 × 14.5 × 18.5 cm

Laser Power One 250 mW laser

Layer Thickness 25 – 300 microns

Save time and produce parts you’ll be proud to deliver, without hassle or extra costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of dental experts.

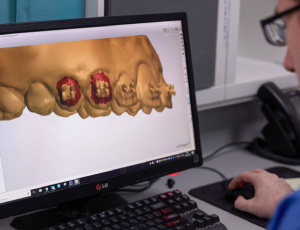

Collect patient anatomy digitally using an intraoral scanner. Send scans to the lab with a digital prescription or to a design station.

Import scan data into CAD software, where the virtual design takes place.

Import the designed CAD files into PreForm print preparation software for print setup and send them easily to a Formlabs printer

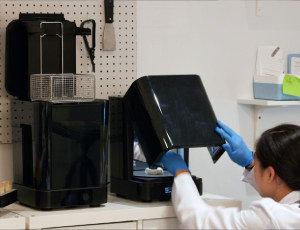

Wash, dry, and post-cure printed parts. These parts can then be used intraorally or be used to produce various indications

Deliver on-demand, personalized care through more effective workflows, quicker surgeries, and better identification and visualization.

Get innovative solutions into patients’ hands faster. 3D printing with Formlabs enables more nimble product development from R&D to production.

Every medical facility should have access to the latest tools to improve care and provide the best patient experience. Get started now or expand your in-house production with Formlabs, a proven, cutting-edge partner in medical 3D printing.

The Form 3B is an advanced desktop 3D printer optimized for biocompatible and engineering materials. Print patient-specific parts in a day at the point of care, or bring quick, impactful R&D and low-volume commercial production in-house.

Download the case study to learn:

Each of our ever-expanding variety of resins has been substantially validated and tested to ensure quality and accuracy.

Plan and manage your print queue in PreForm and manage printers and teams through your online Dashboard.

Form Wash and Form Cure streamline post-processing so you can consistently produce quality results with less time and effort.

testimonials