CNC Machining

WHAT IS CNC MACHINING?

CNC Machining is a subtractive manufacturing process where material is removed from a block with a variety of precision cutting tools to make a component or a product. Advanced software is used to control the equipment according to the design specifications. A team of engineers and machinists program the equipment to optimise cutting time, surface finish, and final tolerance to meet specifications. This technique could create parts with high tolerance (+/- 0.05 mm) in a variety of materials, including metal and thermoplastics.

APPLICATIONS:

CNC machining is used not only to manufacture parts and prototypes but also to make mould tools, which are used for injection moulding or die casting. It is optimal for one-off or low volume custom parts.

HOW DOES IT WORK?

CNC machining is done via milling or lathes. A block of the desired material in plastic or metal is chosen which is machined by high speed cutters controlled by a code. Parts can be machined directly out of engineering thermoplastic plastics and metals. Generally large and bulky parts are economical by CNC prototyping compared to Rapid Prototyping processes.

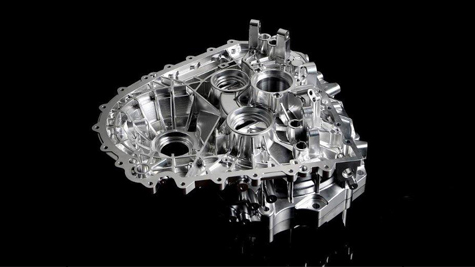

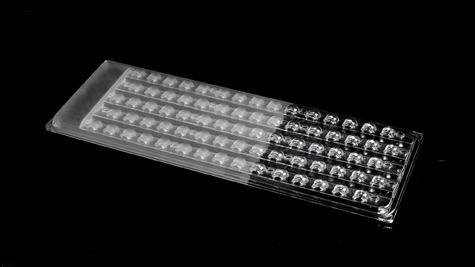

CNC MACHINED PRODUCTS

CNC MACHINING SERVICES

3 AXIS CNC MILLING

The cutting tool moves along the x, y, and z axis while the part being machined is held on the bed by a vice or grip.

5 AXIS CNC MILLING

The cutting tool moves along the x, y, and z axis, the tool head and the machine bed rotate.

CNC TURNING

The material block is held on the spindle which is rotated at high speed and the cutting tool moves radially and lengthwise while machining the block.

MILLING

The material block is fixed to the bed while the rotating cutting tool moves around the face of the block. Mills are all purpose and can handle most machining processes.

ADVANTAGES OF CNC MACHINING

MATERIALS USED IN CNC MACHINING

ABS

ABS is a lightweight thermoplastic material with good mechanical properties and excellent impact strength.

ALUMINIUM

Aluminium has a great strength-to-weight ratio, high electrical and thermal conductivity, and is non corrosive.

MILD STEEL

Mild steel has high machinability, high stiffness, good mechanical properties, and good weldability.

ACRYLIC

Acrylic is a lightweight plastic that is scratch resistant, has reasonable impact strength and is available in optically clear or opaque variants.

Access our entire suite of manufacturing services with Rapid Online Factory In Just a few Clicks.

Log on to rapid.imaginarium.io to turn your concepts into reality today.