Design Meets Additive Manufacturing

Helping Engineering and design teams across the globe in leveraging the full potential of Additive Manufacturing to produce custom parts faster, better, stronger and cheaper.

16 years | 1000+ Customers & Counting

Over 10,000+ customers consulted in last 16 years

Design for Manufacturing is Outdated

Conventional manufacturing processes such as machining and molding are riddled with constraints. Design for Manufacturing (DfM) methods attempt to work around these limitations while staying true to the intended design goal. More often than not, this leads to solutions that rely heavily on standardisation, regular geometries and sub optimal functionality.

Additive Manufacturing, in particular Metal AM, has completely changed the way we manufacture. Unfortunately, old DfM rules overlook the unique capabilities and unparalleled design freedom that AM offers.

Countless engineers have wrongly dismissed AM technologies from their workflow simply because their designs were not optimised to take advantage of these new possibilities. It is about time that we completely reimagine the way products are designed and engineered.

Design for Additive Manufacturing offers a world of opportunities

Design for Additive Manufacturing offers a world of opportunities.

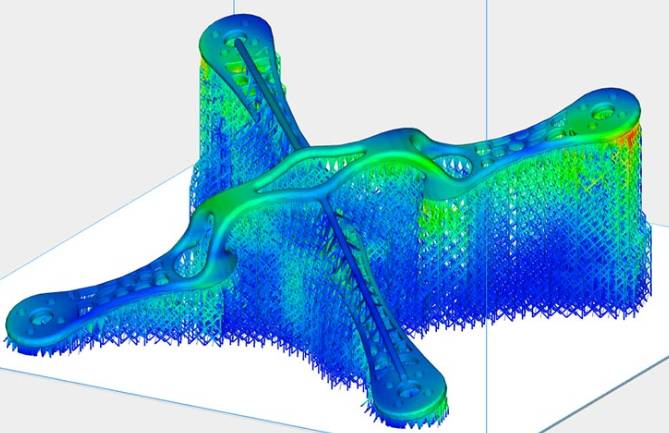

Design for Additive Manufacturing is a new approach to designing parts and products keeping in mind the advantages as well as constraints of AM technologies. Every decision around the use of AM - such as the design, print orientation, process parameters and material properties has a direct impact on the final cost, time, and quality of the part. The optimal selection of these variables unlocks possibilities that were considered impossible just a few years ago.

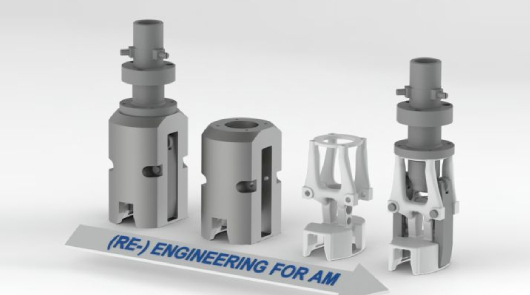

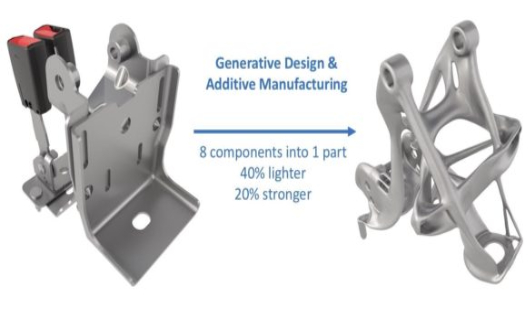

Complex organic geometries, multi-part consolidation, mass customisation, lattice structures and functionally graded materials are just some of these benefits that can lead to immediate technical and commercial benefits for your company or team.

Incorporating DfAM into your workflow can be a daunting task if done without the support of partners who truly understand Additive Manufacturing.

The Imaginarium Way

The Imaginarium Way

DfAM is not a simple linear process that starts with an existing design which is modified for 3D Printing.

At Imaginarium, our approach to Design for AM is more holistic, covering every aspect of design, engineering and manufacturing that work together in harmony to produce the best part possible.

Every project is viewed from three lenses :

System Design

Identifying what parts are suitable for AM

Part Design

The actual design of a part

Process Design

The entire workflow to ensure reliable conversion of digital design into functional product

Here is a look at the Imaginarium Way for DfAM:

Here is a look at the Imaginarium Way for DfAM:

-

Project Consulting

-

Part Identification

-

Re/Design & Optimise

-

Simulation & Analysis

-

Material Development

-

Prototype & Production

-

AM Factory Set Up

Our training programs cater not only to the engineering and design teams, but also to the management and leadership who need to understand how new technologies and design paradigms are disrupting the business landscape, and how they can adapt fast.

Who Needs DfAM?

Who Needs DfAM?

Every company that manufactures products in polymers or metals can benefit from Additive Manufacturing. Here are some of the applications that are made possible when DfAM is used in the right way

Aerospace and Defence

Complex Geometries, Lighter parts, Multi-part integration

Tool & Die Industry

Conformal cooling channel for significantly reduced molding cycle times

Automotive

On demand spare parts, customised accessories, better performing components, reduced lead times

Medical

Patient Specific Implants and Instruments, Prosthetics & Orthotics

Dental & Hearing Aids

Mass customised products, reduced lead time

Jewelry & Luxury

Precious metal products, aesthetically stunning and technically complex designs, personalised products

Get an instant quote and DfAM feedback