Vacuum Casting

WHAT IS VACUUM CASTING?

Vacuum casting is a formative manufacturing process that provides low volume parts with production level quality. This makes the parts suitable for fit and function testing, marketing purposes, and for creating final parts in limited quantitiesa

APPLICATIONS:

VC is used extensively to make functional prototypes for marketing and consumer trials or production parts for lower volume. These trials for new products require functional prototypes without incurring a large cost and time delay. Even though these are low volume production, they consist of a broad range of materials that closely align with final production materials such as plastics, threads and inserts, multiple cavity tools, and overmoulding.

HOW DOES IT WORK?

Vacuum casting begins by making a master sample out of SLA which is then used to create a silicone mould by casting silicon around the master. Once the mould is set, it is cut along a predetermined plane and the master is removed. The mould is used to create a new product made from polyurethane which mimics nearly 85% of the mechanical properties of thermoplastic material, creating a nearly identical prototype that is trial ready

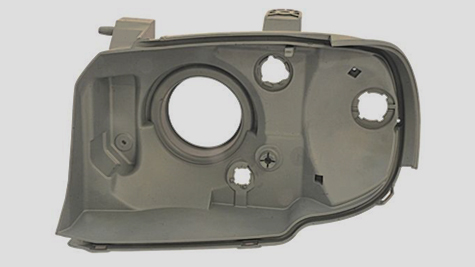

VACUUM CASTING PRODUCTS

ADVANTAGES OF VACUUM CASTING

MATERIALS USED IN VACUUM CASTING

ABS

Acrylonitrile butadiene styrene is popular due to its low production cost. Imaginarium offers ABS like material in PX223 (Axon) and SG95 (Renishaw)

PP

Polypropylene is one of the most widely used plastics and is very easy to mould. Imaginarium offers PP like material in 8045 (Renishaw)

GLASS FILLED MATERIAL

Glass filled polymers increase structural strength, impact strength, and rigidity. Imaginarium offers Glass filled (30%) material in VC3368 (Alchemi)

PC

Polycarbonate offers high impact resistance and is available in transparent variations. Imaginarium offers PC like material in Transparent 5210, 1810

WAX

Wax can be formed into nearly any form imaginable and offers the ability to create surface textures. Wax is available in the form of wire, sheets, and sprues.

RUBBER

Rubber like materials are tough and have good tear strength. They’re ideal for gaskets and seals. Imaginarium offers rubber like material in 8891, UPX 8400.

Access our entire suite of manufacturing services with Rapid Online Factory In Just a few Clicks.

Log on to rapid.imaginarium.io to turn your concepts into reality today.