Allied Services

WHAT ARE ALLIED SERVICES?

Allied services are formative manufacturing technologies that use suitable stresses on a material to form a product. These technologies can be completed using a wide range of materials including metals and plastics. The benefit of using these technologies is that you can make a single product with different materials at the same time. Formative manufacturing also allows creative and financial flexibility.

ALLIED SERVICES PRODUCTS

ALLIED SERVICES ON OFFER

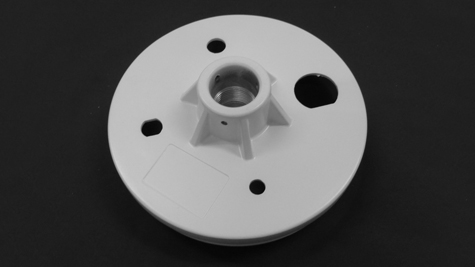

COMPRESSION MOULDING

Compression moulding is used to shape thermoplastic and thermoset material by placing it in a mould cavity and forming them by applying heat and pressure. Semi heated material (in the form of granules or pellets) is placed in a mould and pressure forces the material to fill up all the cavities of the mould. Heat and pressure is maintained until the material cures and the excess product (flashing) is removed by an experienced finishing team to maintain exact measurements. Compression moulding allows the moulding of large, intricate parts and is fairly cost effective.

INVESTMENT CASTING

Investment casting makes parts from molten metals. Wax or 3D printed replicas are made and assembled into one big pattern which is ‘invested’ into a slurry that hardens in the mould. The wax pattern is melted out from the mould, and molten metal is poured which takes the exact shape of melted pattern. The material is allowed to settle and cure once the mould is broken. Investment casting is preferred when the parts are complex and intricate. It can be done in a variety of metals including Gold, Silver, Brass, Bronze, Aluminium, Stainless steel alloys etc.

PRESSURE DIE CASTING

Die casting is a process where molten metal is forced into a mould cavity under high pressure. The mould cavity is made using two hardened steel dies and the process is similar to injection moulding. Die castings generally have very good surface finish and dimensional consistency.

SHEET METAL

Sheet metal fabrication includes cutting, forming, bending, forming, machining, and assembling multiple workpieces into a product. Once the product is formed, finishing is required before the product is ready for the market. It can be done in a variety of metals like Aluminium, Zinc, Nickel, Tin, Brass, etc.

REACTION INJECTION MOULDING

Reaction moulding is similar to injection moulding except thermosetting polymers are used and require a reaction in the mould. The polymer may be mixed with another polymer and is fed into the mould under low pressure where it is allowed to sit in the mould for long enough to expand and cure.

Access our entire suite of manufacturing services with Rapid Online Factory In Just a few Clicks.

Log on to rapid.imaginarium.io to turn your concepts into reality today.