Imaginarium is the leading advanced digital manufacturing solutions and services enabler in India offering integrated services to form multi-part assemblies in addition to small-part printing solutions. Explore the full potential of additive manufacturing with India’s premier advanced digital ecosystem.

With more than 15+ years of experience in the additive manufacturing field, Imaginarium is propelling India to become a leader in advanced and digital production. It strives to magnify Indigenisation with its latest investment dedicated to enabling the adoption of additive manufacturing, creating end-use high-precision parts.

Our Reach

Imaginarium is making digital strides by pioneering healthcare applications such as custom surgical guides and fixtures, patient-specific implants and orthotics. Our bio-medical experts work with professionals in Orthopaedics, Anthropometrics, Dental, Cardiology, Neurology, Cranio Maxillofacial, Oncology, and more.

Imaginarium impacts healthcare providers with inclusive benefits and medical application support.

- Patient-Specific Solutions

- Surgical Simulations

- Design Freedom

- Cost-Effective

- Quick Turnaround Time

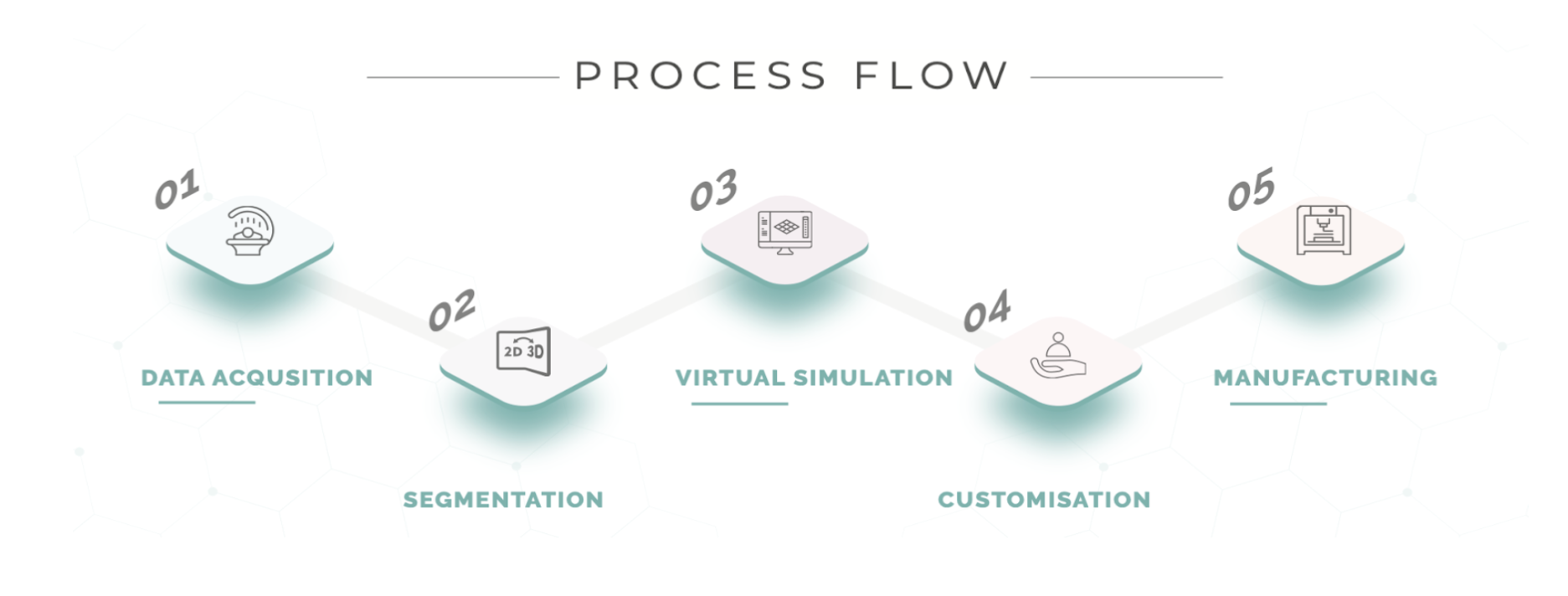

Our Process

Imaginarium’s 3D printing capabilities have revolutionised the digital landscape regarding customisation and patient personalisation demands in the medical and anatomical sectors.

Our team follows the processes by transforming medical CT Scans into 3D files that can be analysed and reworked via computer software and produced using additive manufacturing techniques.

Additionally, these steps are in tandem with producing an end-use part either internally or externally. Creating a segmentation of the MRI or CT scans is one of the first steps of virtual planning. This then helps ideate and virtually conduct the surgery to mitigate the risk of surprises and poor outcomes. . Once approved by the doctor, the personalised surgical guide is designed and printed to use during surgery, drastically reducing operation time.

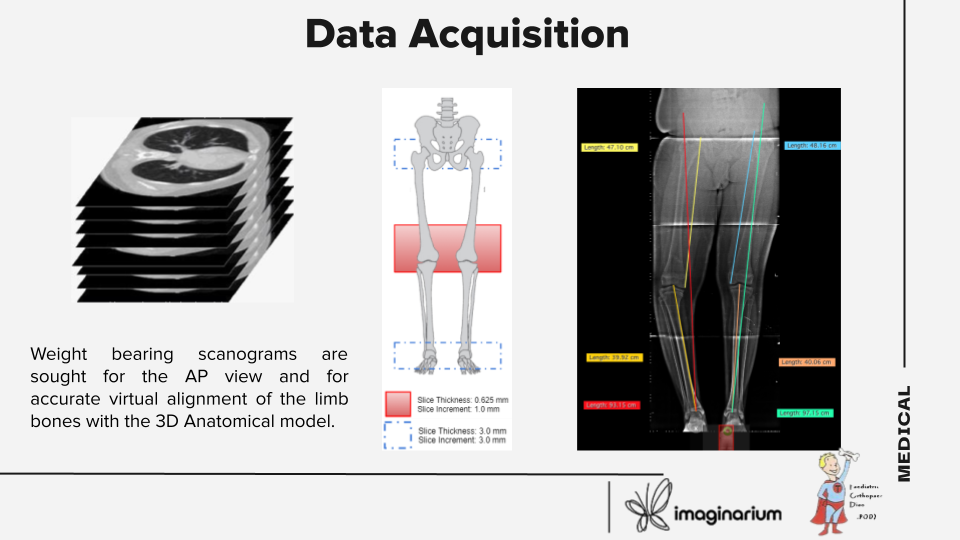

Imaginarium Life’s Data Acquisition and Process Flow

Condition:

Genu Varum (Bow Legs)

Case:

14-Year Male, diagnosed with Genu Varum, commonly known as Bow Legs.

It refers to the outward deviation of the longitudinal axis of the femur and tibia, medial angulation of the knee leaving space between the legs.

Under the supervision and care of Dr. Taral Nagda, a Pediatric Orthopedic Surgeon at Jupiter Hospital, Thane, the case was successfully completed with minimal risks involved.

Swipe to know more about Operating Specs

The Challenges:

Traditionally, these have been planned on radiographs (CT scans), two-dimensionally not offering the complete picture or understanding of the deformity.

This particular genetic disorder affects the patient’s walk and ligament structure among other physical problems such as

- Difficulties in gait.

- Ligamentous instability.

- Malalignment of the patella.

- Knee discomfort.

Additionally, Osteotomy procedures require careful planning and execution and carry their own risks such as neurovascular injury and implant-related complications. Operating time can be hours long and still not guarantee ideal limb correction.

The Imaginarium - Formlabs Solution for Personalised Advanced Healthcare

With virtual planning in-house by biomedical engineers and with the help of cutting-edge 3D printers such as the Formlabs 3B, Imaginarium Life develops customised healthcare solutions.

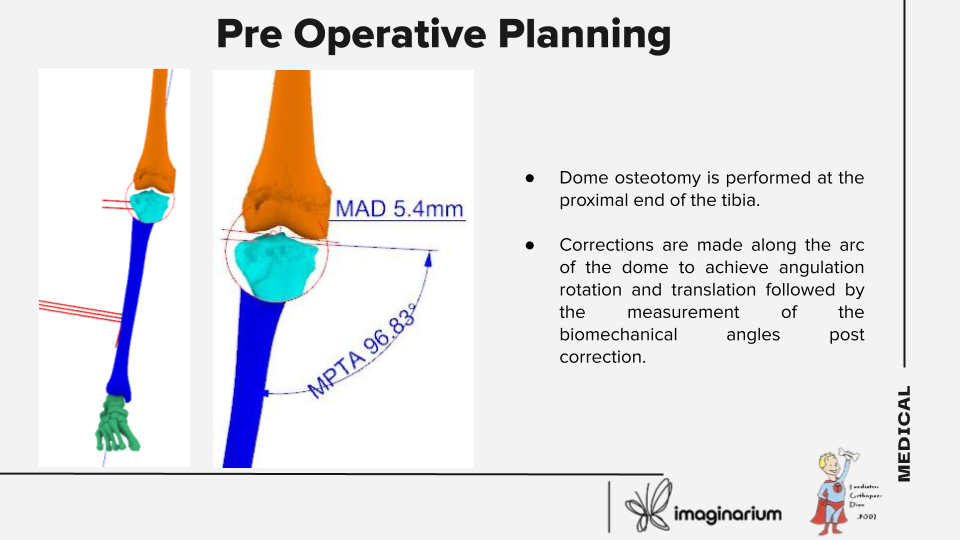

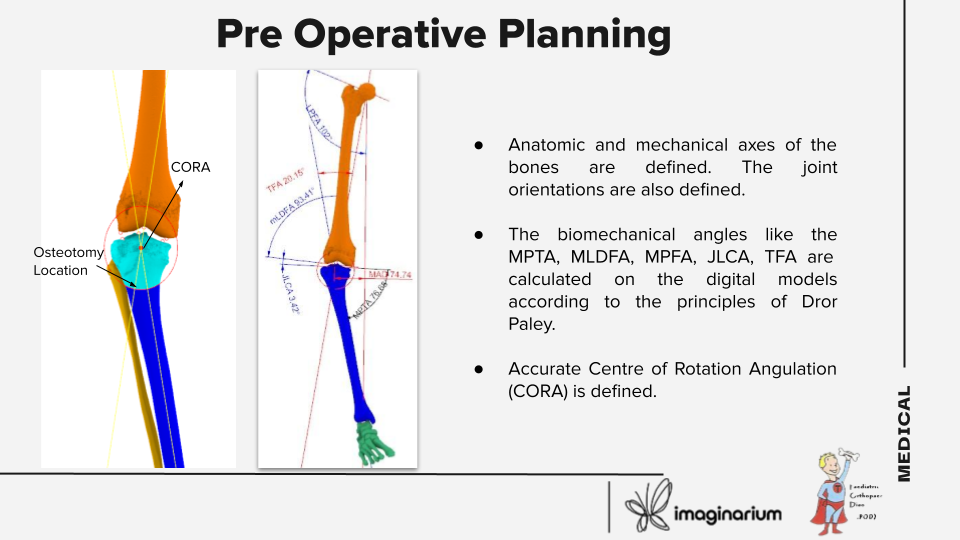

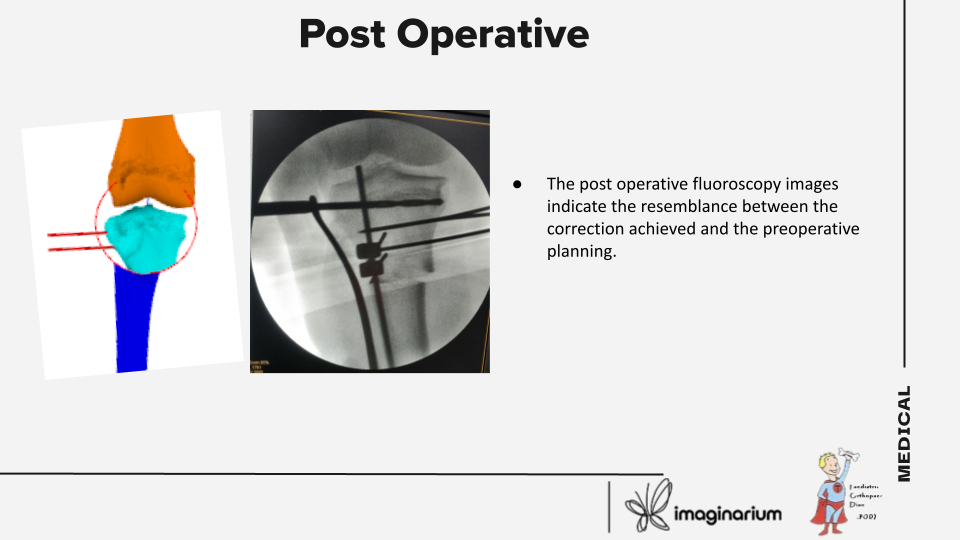

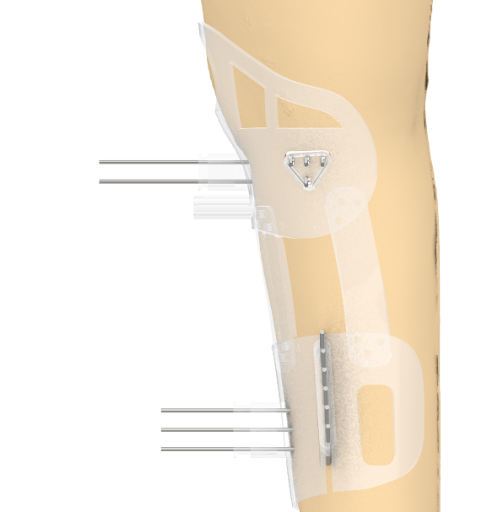

In this case, the limb deformity was corrected via the procedure called an Osteotomy, using careful surgical planning and medical execution.

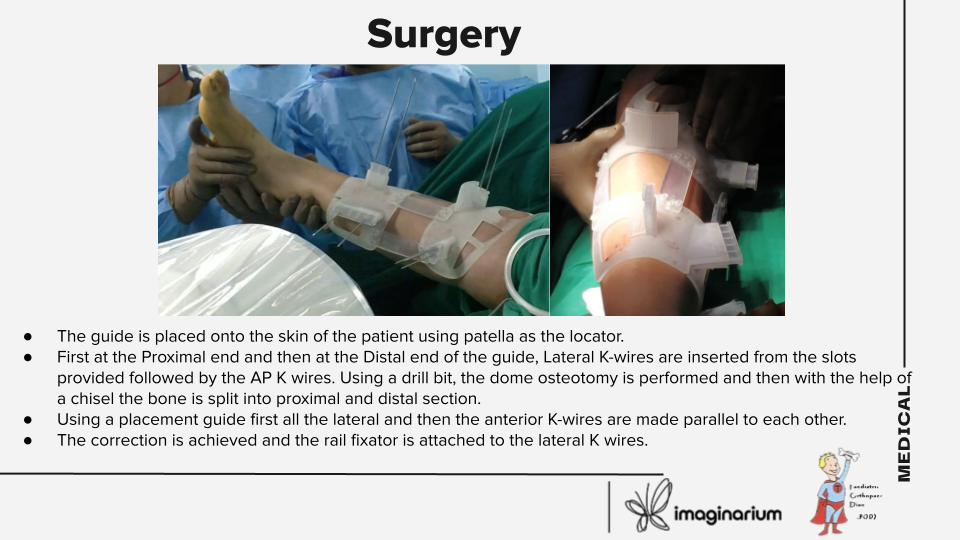

Working with Dr. Taral, Imaginarium’s Life team began by segmenting the patient’s CT scans into a 3D structure. This allows easy recognising and analysing of the data acquired. Post-segmentation, the surgery is planned and simulated virtually with the doctor. This allows the team to make accurate calculations and virtual surgical decisions leading to the ultimate precise result and deformity correction.

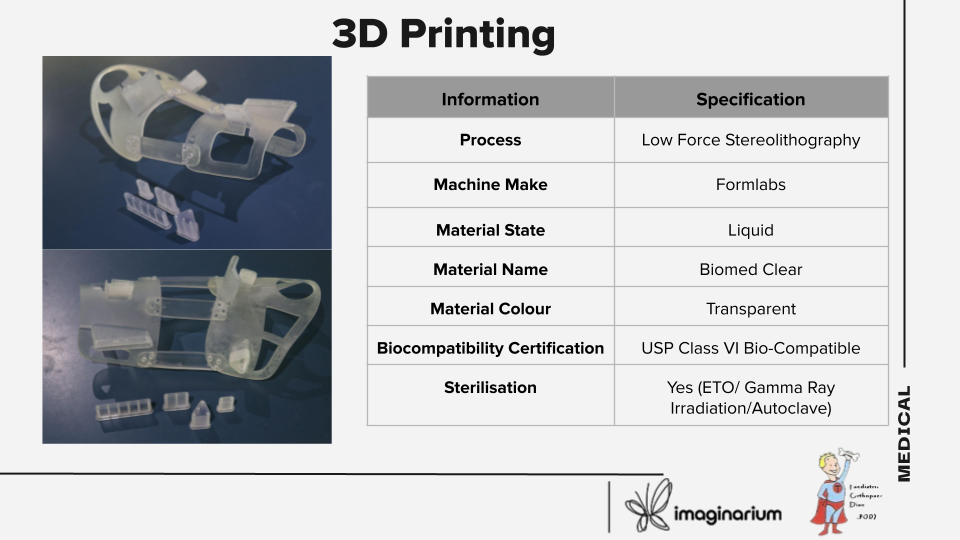

Formlabs 3B used to create custom surgical guides

Dr. Taral Nagda appreciated the team's work by saying, “We have been working with Imaginarium Life and Formlabs’ printers to create personalised surgical guides for our osteotomy cases. Using customised surgical guides ultimately benefits the patient and the surgeon, by reducing the OT time and recovery time. Creating the perfect 3D-printed guide for any patient requires precision and planning allowing for the highest accuracy in the surgery.”

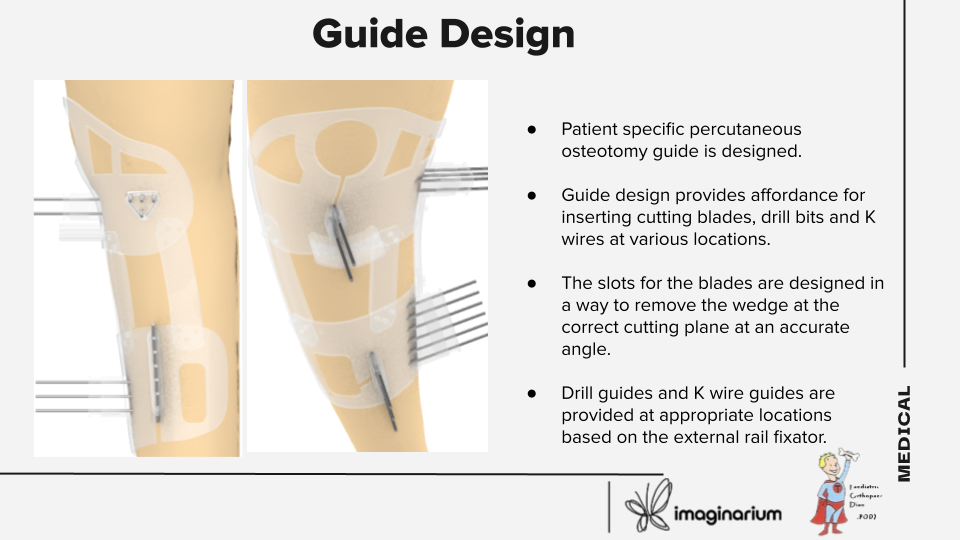

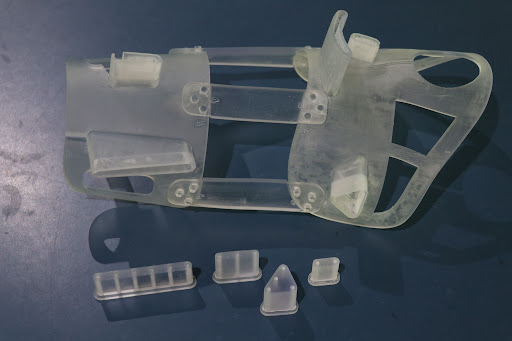

Custom Surgical Guide made in the Genu Varum case post-print (left) and virtual visual on-skin placement (right).

Our team built a customised surgical guide using Formlabs’ Form 3B printing technology in only 8 hours. It helped achieve high precision in the Osteotomy with a quick turnaround time.

The Formlabs LFS printing technology was chosen over the SLS technology since the material was much more rigid and provided output in 8hrs. With no post-print cooling required, the Formlabs LFS technology drastically simplified the patient-specific surgical guide manufacturing process.

Technology | SLS | Formlabs LFS |

|---|---|---|

Material | PA-12 | Biomed Clear |

Colour | White | Transparent |

Rigidity | Low | High |

Print time | 16 hrs | 8 hrs |

Printer Cooling time | 8 hrs | None |

Post Processing Time | 30 mins | 2 hrs |

Technical Specs of the Personalised Surgical Guide

Imaginarium Team's Virtual Planning for Ideal Osteotomy Procedure in Genu Varum

Conclusion

The process traditionally was slow and time-consuming but with the speed and high precision of custom-built surgical guides and medical instruments, utilising the Formlabs ecosystem, complex medical cases are now quicker, more efficient and low-risk.

Our in-house 3D-printed, customised percutaneous surgical guides help healthcare professionals achieve high-precision outputs for complex surgeries. Furthermore, it helps cut back on the operating duration and allows for less invasive procedures.

Greater accuracy - Implant Positioning & Bone Resection.

Limited conventional instruments used.

Reduces the exposure of X-Rays to the patient and the OT staff.

Lower risk of surgical complications.

Precisely replicate pre-the surgical plan.

Imaginarium Life is focused on providing impactful healthcare solutions to facilitate a better quality of life. For more information on our products and services - https://imaginarium.io/

Medical Team Contact:

Connect with our Medical Experts at +91 22 6738 0100

Email us on life@imaginarium.io

Press Contact:

Imaginarium

press@imaginarium.io

Formlabs

press@formlabs.com