Challenge:

Today, the energy industry is under constant pressure to make oil and gas extraction more efficient, quick and cost-effective. One of the most effective ways to do this is through a digital approach that assists in democratising manufacturing of obsolete and legacy spare parts, prototype faster and fulfill all on-demand manufacturing needs. Imaginarium is a one-stop solution providing manufacturing needs based on the exact requirements. Our client, leader in providing engineering and construction solutions to the energy industry, approached us to assist them in producing their spare parts efficiently using the correct manufacturing technology. After receiving the old and obsolete parts from the client, our team had to manufacture the new parts without the original design in record time using the best manufacturing technology available.

Time:

15 days

Material:

AL 6082, MS 1018/MS 2062, 4140, EN8/EN9

Solution:

Imaginarium adopts a comprehensive design to manufacturing approach for spare parts manufacturing. In the oil and gas industry, spare parts are like the Achilles heel. Today the companies are forced to maintain an extensive inventory of a large variety of spare parts and components to try and minimize production losses resulting from equipment breakdowns. Though companies invest hundreds of millions of dollars in slow-moving inventory, companies still suffer billions of dollars of lost production value every year. Many companies try to optimize the conventional supply chains, however, the real impact remains negligible compared to the underlying issues. The biggest problems and inefficiencies in the logistics of parts for the Oil & Gas companies are only increasing and energy companies are continuously trying to overcome them.

A leading Engineering Service Provider, our client had spare parts that were obsolete and needed to be redesigned and updated to fulfill new functionality. As a result, the client established a partnership with Imaginarium, one of the World's most integrated Digital & Advanced Manufacturing companies, in which they tapped into the company’s Reverse Engineering

technology and other manufacturing services to create new spare parts with functional enhancements as well as make them much lighter. Imaginarium is a leader in 3D Printing, Rapid Prototyping, Advance Manufacturing and Reverse engineering services for legacy spare parts, parts modernization and advanced product development. Our engineers followed a step-by-step manufacturing process.

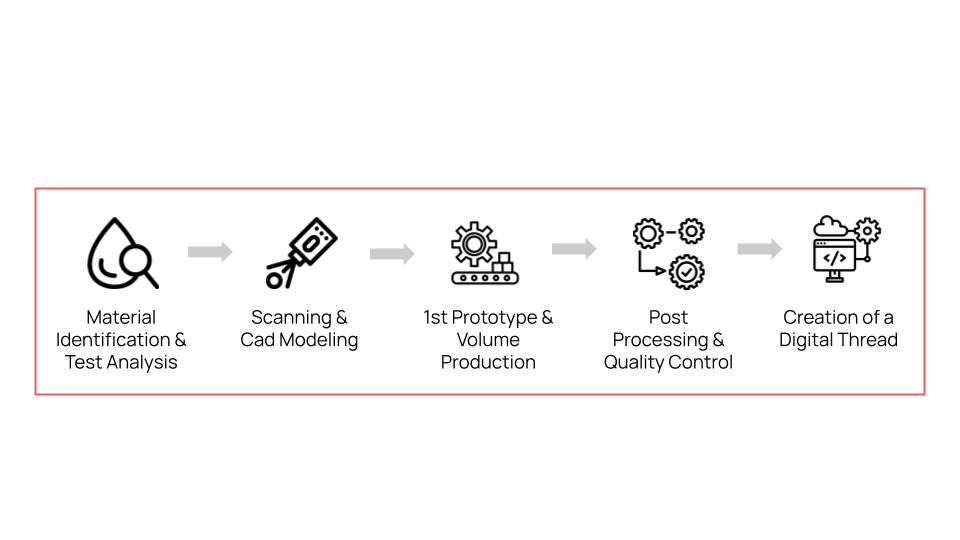

On-Demand Spares Manufacturing Process

On-Demand Spares Manufacturing Process:

Step 1: The material testing of the old parts was done through positive material identification and spectroscopy test. Our polymer scientists and metallurgists identified the materials, the quality grade and the malleability. The materials identified were AL 6082; MS Grade CR2 and MS Grade CR4 with testing standard 513:2008; metal alloys with grade 42 Cr4Mo2 and 40NiCrMo3. Our experts found that metal doesn’t need to be malleable as the new part could be manufactured from a whole piece and didn’t need different material sheets

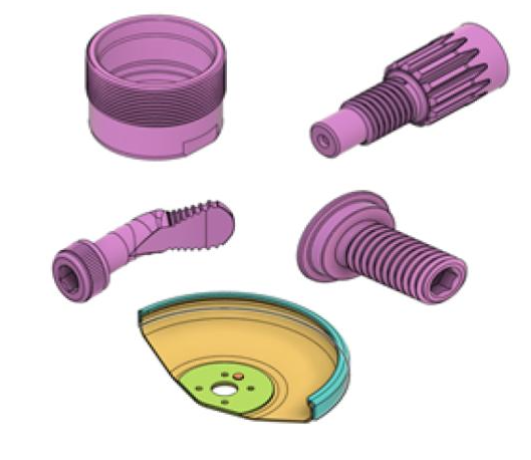

Step 2: The next step included the use of 3D scanning/ reverse engineering to create 3D models. A 3D CAD model assists in on-demand manufacturing, controlling the design and re-design and shortening the lead time.

Scanning/ Reverse Engineering and other Analytical Techniques Used to Create 3D Model.

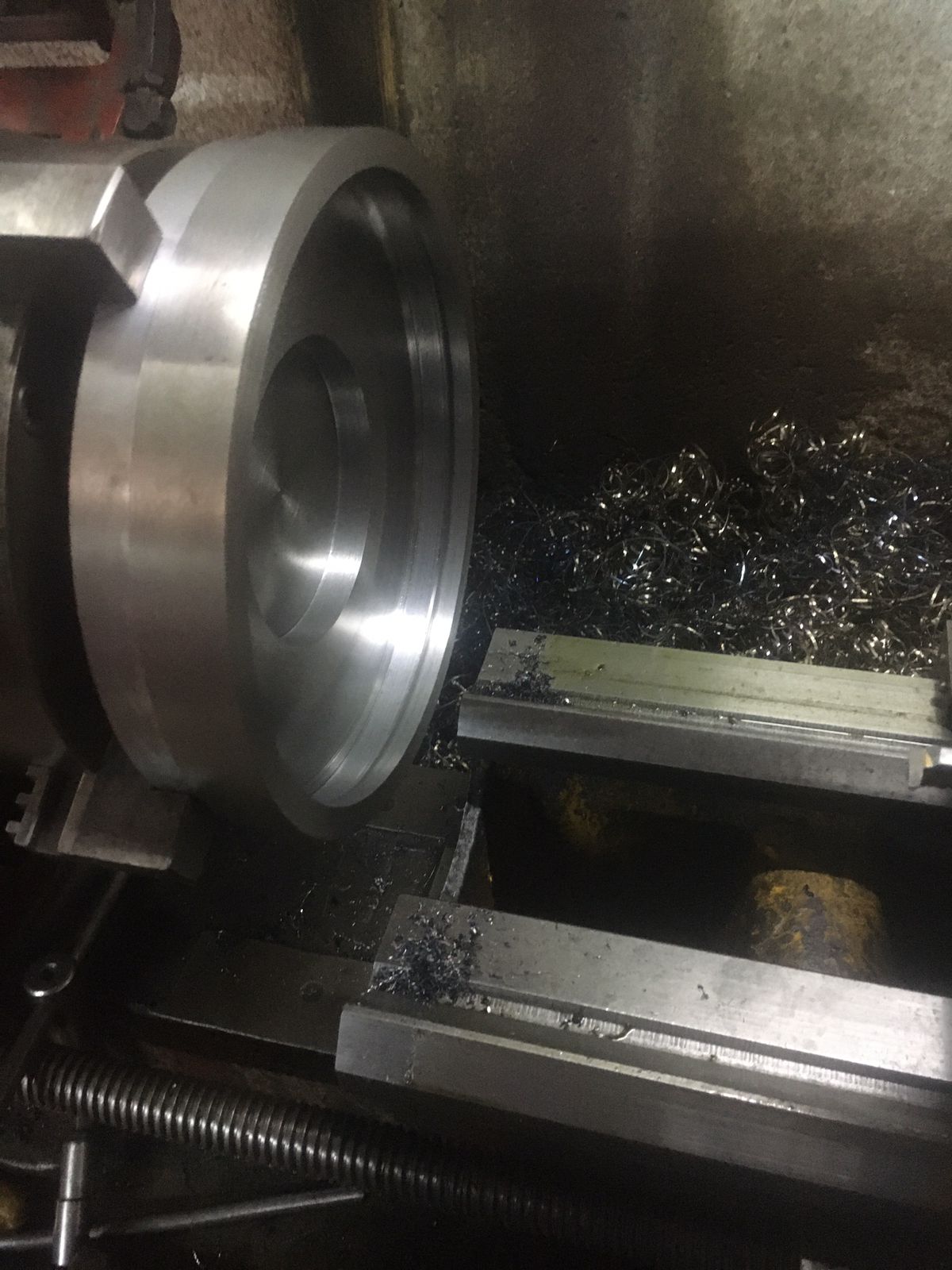

Step 3: Our client wanted a cost-effective and quick manufacturing process for their spare parts so our experts suggested using CNC machining for all the parts.

CNC Machining

Step 4: Once the parts were manufactured, it was time for post-processing and quality control. Anodizing was the post-processing technique used and thorough quality checks were conducted. The selected post-processing technique, anodizing, effectively increased the abrasion and corrosion resistance of the parts and also enhanced the visual appearance. The material was tested under Test Method IS 8811: 1998.

Post Processed Part - Anodizing

Imaginarium is well backed by advanced manufacturing technologies that provide the best production services in quick turn-around times. From the initial old part delivery from the client end to the manufacturing of new parts using reverse engineering, Imaginarium completed the whole project in just 15 days. Our client was ecstatic with the results. It was not only cost-effective but also manufactured in a shorter period using CNC machining technology.

Old Obsolete Part & New Part Manufactured by Imaginarium

The oil and gas industry is facing several challenges continuously like the lead time to get spare parts is too high, or the OEM has stopped making parts and even the parts have become obsolete. With reverse engineering, oil and gas companies can opt for inventory less management and control design and re-design. It is also possible to create a digital inventory and only manufacture parts when needed.

Our client who is a huge name when it comes to providing engineering and construction solutions to the energy industry believed that the current oil and gas industry was going through a phase of reshaping itself due to the current market dynamics. The company representative said that there has been a rise in unexpected incidents where obsolete spare parts are not being manufactured anymore and even finding the original drawings for critical components has become challenging. When our experts used reverse engineering technology and delivered the parts in record time, he was satisfied and even praised Imaginarium for the expert job done.

Imaginarium is a leader in 3D Printing, Rapid Prototyping, Advance Manufacturing and Reverse Engineering for legacy spare parts, parts modernization and advanced product development. We assist companies who face challenges in producing their obsolete and legacy parts. With over a decade of experience in additive manufacturing as well as subtractive manufacturing technology, our expert team at Imaginarium is always on their toes to assist you by providing a working solution for your needs.