Time is money. Do you also wonder how you can be more efficient, productive and save time? Well, we at Imaginarium have tried quite a few things and one of the best we discovered was using Autodesk PowerMill 2022 for CNC machining. One of our clients’ was actually able to reduce their machining time by a whopping 52% when they used Autodesk PowerMill 2022.

Imaginarium, your go-to consultant for customized expertise and Diligent assistance in the manufacturing industry, is well equipped with highly qualified engineers and CNC experts. We offer our clients a wide range of 3D Printers, materials and software solutions that enable everyone from individuals and businesses with tailored solutions for their manufacturing needs. For instance, one of our clients wanted to update their Autodesk PowerMill and experience how automation can save time and avert manual errors.

The Challenge:

Our client wanted to design a fixture that could hold the block of material, plastic or metal, for 3-axis CNC machining set-ups and reduce their machining time. Whether our client wanted to cut or mill or even drill a hole in the material, he needed a fixture that could automatically move the material in a specified direction without much manual intervention. Our client also wanted to know and experience the new features of Autodesk PowerMill software to save time and increase productivity.

The Solution:

Autodesk PowerMill 2022

The Highlight:

Reduction in machine time by approximate 52%, eliminating the need for a 5-axis CNC machine for a few of their projects.

Time:

2 Days for Product Delivery and less than six days for client training, demo and on-site visits.

The Power of PowerMill 2022:

Imaginarium is a distinguished Autodesk partner offering Netfabb, Fusion 360, Powershape and PowerMill software to clients across various industries. We empower businesses with effective solutions across their manufacturing processes. Our client has an entire suite of manufacturing services to offer high-quality products for one-off prototypes as well as series production for 1000s of parts. They counted on Imaginarium, the industry experts, for a solution that could reduce their machining and programming time and provide several other benefits. Imaginarium engineers proved to be a boon for the client with the best solution. Having tried and tested the new PowerMill 2022, we knew this was the perfect option for our client.

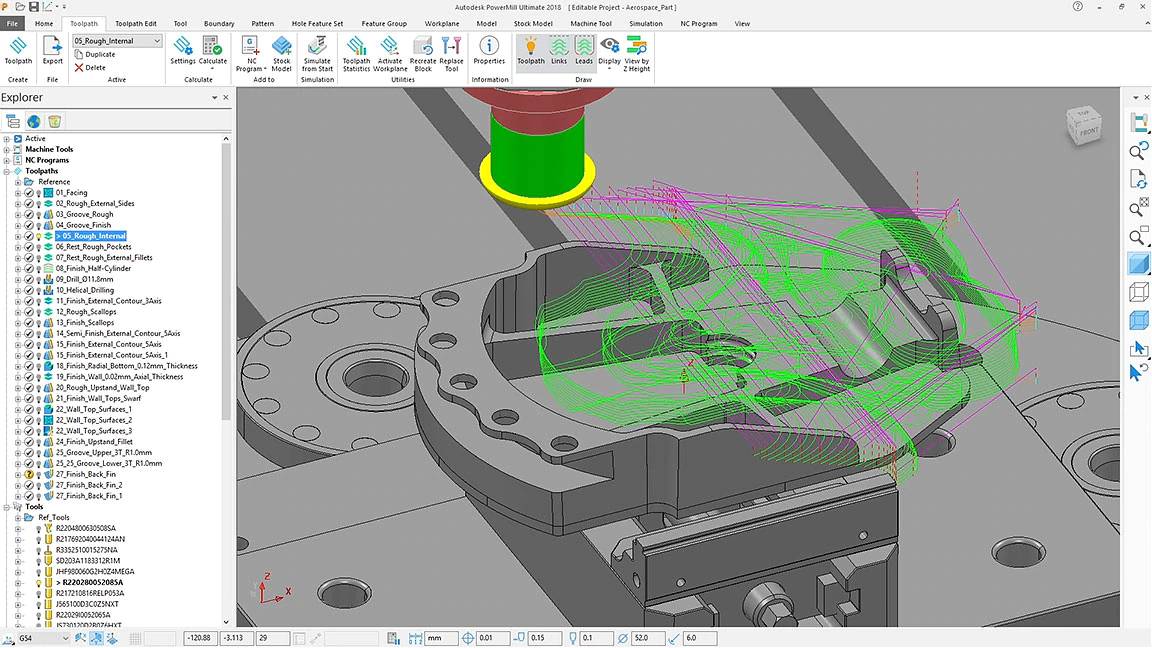

Autodesk PowerMill is an expert CAM software that assists moulds, dies and complex component manufacturers to achieve maximum quality, control and efficiency from their CNC machines. It has automated programming with macros and templates. It can create a high-quality toolpath on large and complex parts. With the new PowerMill 2022, the client could access a comprehensive library of toolpath strategies that assisted in manufacturing exceptional quality parts. In addition, the templates could avert many manual errors. The perfect toolpath template for the fixture was created using the PowerMill software. Autodesk PowerMill 2022 was a one-stop solution for our client's 3-axis CNC machines as it came with an array of features and even improved the quality of flat machining. As a result, parts with complex design and critical components like sharp internal corners could be manufactured accurately. PowerMill 2022 also assisted in reducing the set-up time considerably and assisted in creating probing tool paths to measure parts with spindle proves. Other features provided the ease of programming for multiple set-ups and a stock model for understanding the left-out material.

The Autodesk PowerMill aided expert performance through the rapid calculation of tool paths for large and complex parts. In addition, it assisted in reducing the maintenance costs due to its high-speed roughing and prolonged tool life. It also helped in simulation, collision and gouge checking, which helped in generating an optimised tooth path with the minimum possible cutter overhang. This software also assisted in minimising the machine time and achieving the desired quality product.

The Final Output:

We provided our client with Autodesk Powermill 2022 in just 2 days after the confirmation. The CNC manager exclaimed that this software worked like magic for their CNC machines. He said, “With PowerMill, we were able to eliminate the need for a 5-axis CNC machine for quite a few of our projects. Our machine time was reduced by approximately 50-52%. We achieved excellent surface finish with solid dimensional accuracy for our parts and also the need for machining with a large overhang was eliminated.”

Our client was thoroughly impressed with our technical expertise. Our well-trained and experienced team visited the client-end and provided proper training along with the technical demo. In addition, our representatives calmly answered all the queries raised by their team and provided the best post-sales service and handheld the client's team excellently throughout their learning process.