3D Printing is a highly disruptive advanced technology changing everything about traditional manufacturing, including the food and beverage industry. Manufacturers and enterprises across a broad spectrum of industries such as aerospace, automotive, jewellery, healthcare, packaging, and even food are actively piloting and leveraging the inherent benefits of 3D printing technology. There has been steady progress in 3D Printing materials since the 1980s, from thermoplastics to metals and now even food. Major brands like PepsiCo, Hershey, and Oreo use 3D Printing in novelty applications like custom-shaped potato chips, chocolates, and cream patterns. 3D Printing in food, a growing sector, is changing how food is produced, stored, packaged, and delivered.

Matmatch.com

The food industry grew amid the global pandemic when the world was brought to a standstill and an increasing demand for sustainable health and nutritious food options. One such technology emerged was 3D Printing, where 3D Printers like Foodini printers increased productivity, printed healthy food and maintained quality.

Ways 3D Printing is Changing the Food Industry

3D Printing is revolutionising how we produce and consume our goods. It is transforming food production and innovation through creativity, customisation and sustainability. Here are some ways how 3D Printing is changing the food industry.

Redesigning Brewery Plant Parts:

In partnership with GE Additive, Kaspar Schulz identified a few parts that could be improved through the 3D Printing technology. One such component was the racking arm of the Lauter Tun vessel. The vessel is responsible for separating wort (the liquid that comes from the mashing and beer from solids), and the team was looking forward to increasing the filtration efficiency of the spent grain in the vessel. GE Additive and Kaspar Schulz developed a thinner blade with internal channels that allowed water dispersal throughout the bed and loosened spent grains in the vessel. This feature increased the yield and processing time. Additive manufacturing proved to be a key benefit in functional integration by reducing the need for seals and joints.

3D Printing In Food Packaging Line:

Today, inventory management is a serious issue for many companies, especially for those food productions that are often on sale. The traditional methods of storing and tracking inventory are inefficient and costly. For instance, if a company produces 10 million servings of a specific dish, there are significant chances of food waste due to insufficient inventory. In addition, the logistics involved in maintaining large amounts of inventory can be extremely complicated. 3D Printing allows for the customisation of products, reducing wasted inventory. It also allows for small batch size manufacturing, so 3D manufacturers can print out single servings of their products for clients to try and produce more based on the demands.

3D Printing & the Food Industry

Today, an individual needs to consume a meal containing a precise set of ingredients and appropriate nutritional values. Food-grade 3D Printing is a ground-breaking technology that can improve the nutritional value of meals and even address hunger issues in countries where fresh and affordable ingredients are inaccessible.

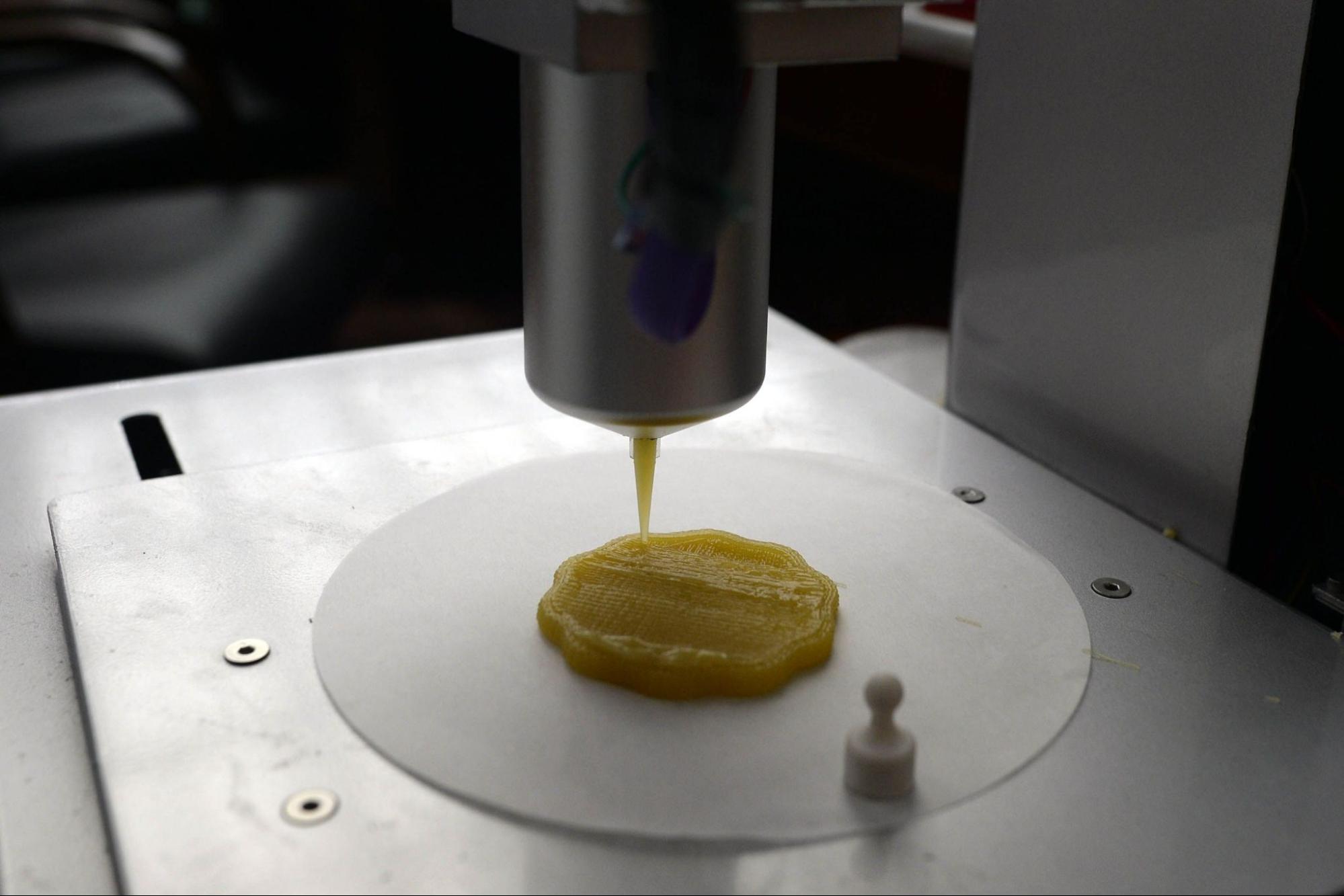

3D Printers extrude thermoplastic and even titanium filaments. 3D food printers extrude food material and deposit it through a nozzle guided by an STL file derived from CAD data. The digital information directs the nozzle to deposit “build material” one layer at a time. The extrusion process in a 3D-binding printer requires food of even consistency and proper viscosity for two key reasons: First, it must emerge smoothly from the nozzle. Second, it must maintain its shape upon deposition.

Some foods that begin as liquids cannot be extruded, like flavoured gelatin. In such cases, Stereolithography (SLA) technology is used to take data directly from the CAD software to create moulds that can be further used in food production.

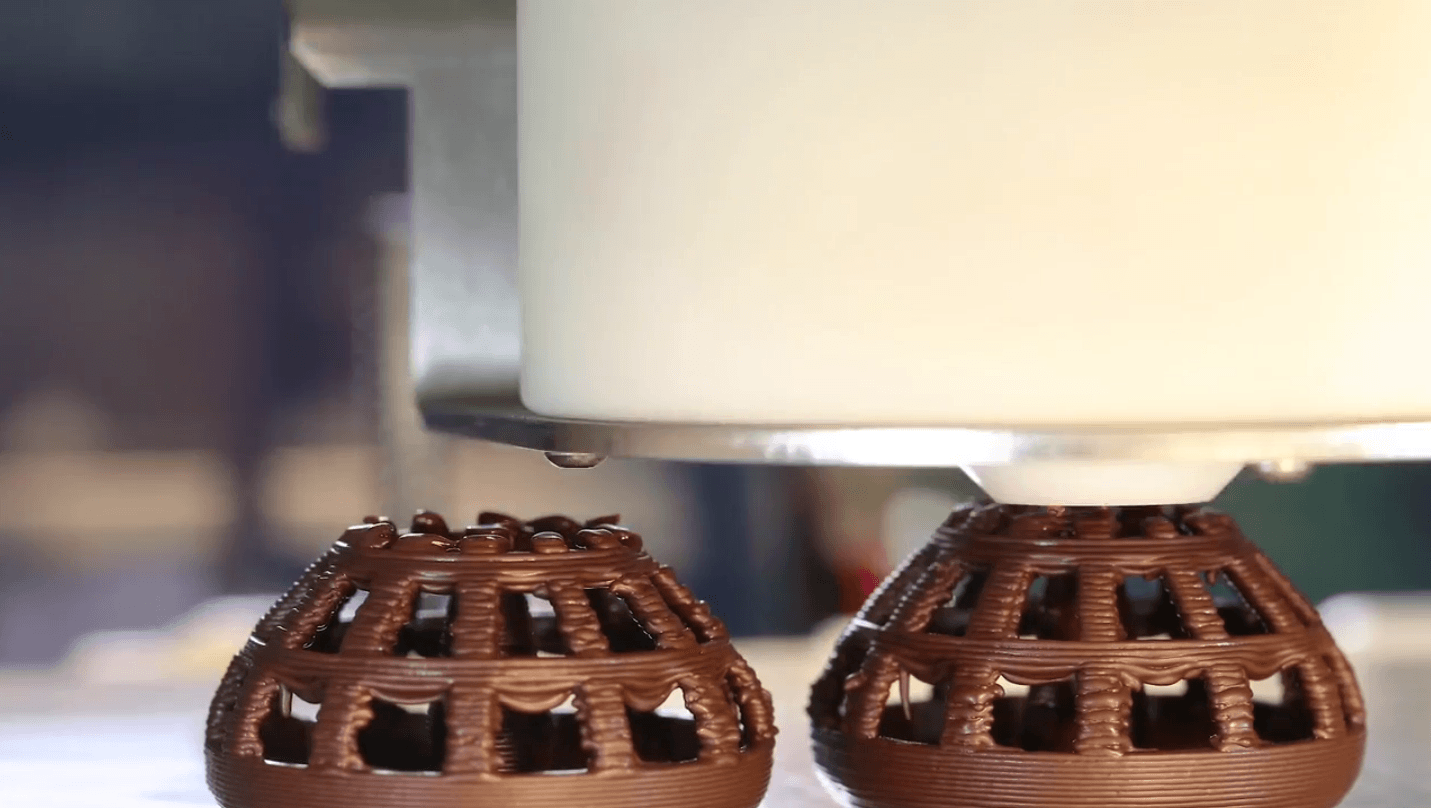

Different 3D manufacturers use different types of 3D food printers based on food material type and raw materials. For example, 3D Systems Chefjet uses crystallised fine-grain sugar for perfect geometric configurations and high-throughput confectionary. Other 3D Printer companies prefer using syringes to dispense chocolate into beautiful patterns. In contrast, Foodini Printers use edible ingredients squeezed out of stainless steel capsules to create a wide range of dishes from sweet to savoury.

| 3D Printer Type | Food Material Type | Raw Material Used |

| Extrusion Base | Soft foods (chocolate, cheese, dough, and meat puree) | Polymers, hydrogels and biogels |

| Inkjet-based | Low viscosity materials (fruit puree and pizza sauce) | Liquid/ solid phase (ink, fruit concentred, and fruit juice) |

| Binder jetting | Powdered materials (sugar, starch, and flour) | Sugar and starch mixtures |

| Selective Laser Sintering | Powdered materials (fat chocolate, and sugar) | Non-sticky powdered materials without any tendency to agglomerate |

Brands Using 3D Printing

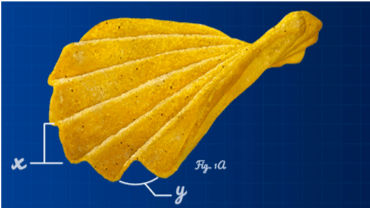

Pepsico

Created plastic prototypes of different shaped and coloured potato chips.

Oreo

Customized creme patterns and flavours of cookies

Hershey

Uniquely Designed Candy

Barilla

Sponsored a contest to create a 3D Printed Pasta

AlgaVia

Utilized microalgae to develop a non-allergenic, gluten-free, high source of dietary fibre protein powder.

Advantages of 3D Food Printing

Health Benefits

3D food printing is a boon for health-conscious people and the growing trend of veganism and gluten- and lactose-free diets. 3D Printers can be connected to an independent fitness tracker that measures calorie consumption and assists with customized meals. Additionally, one can also determine the number of vitamins, carbohydrates and fatty acids and even assess the correct percentage of nutrients for a particular age. 3D Printed food can also be used for hospital patients to ensure they get a nutritious meal while taking care of all the food restrictions.

Save Time & Energy

3D Printing saves both time and energy when it’s about experimenting with different types of food dishes as it helps achieve perfection with less effort and time.

Creativity

3D Printing enforces innovation and creativity. It assists the chefs who want to experiment by trying different combinations of dishes or making dishes in less time or with less material.

Food Wastage

3D Printing cuts down wastage by reproducing the food that is edible and also looks good. The leftovers can be recycled in a more attractive form and kept in the food chain. Many restaurants and supermarkets can save tonnes of food using this technology.

How Successful Is 3D Food Printing Today

3D Printing is not just limited to making plastic toys anymore. It is used in almost every field and assists major brands in saving time and money. NASA awarded a small business innovation research (SBIR) Phase 1 contract to a Texas company called Made In Space to explore the potential for printing edible food on deep space missions in 2017. The program’s goal was to get astronauts to eat nutritious meals while travelling through space. NASA hoped that the 3D Printed food would not only save them money but also help them stay healthy during long journeys.

3D printing technology in the food industry can fulfil the unmet needs in terms of personalized nutrition, food wastage, demand, and food availability. Food product customization, product innovation and manufacturer-to-consumer partnering are just the beginning of where this technology can go ahead. Furthermore, the world’s population is increasing rapidly, causing not only an increase in demand for food but also food wastage, leading to food source scarcity. 3D Printing technology can efficiently use food resources with no or significantly less waste. Therefore, it can be rightly said that 3D Printing is not just revolutionizing but also the future of the food industry.