Did you know that colour 3D Printing has been around since 2005? Though being relatively young, additive manufacturing offers a lot of design and manufacturing solutions. While many 3D printing technologies print in a single colour, there are a few fascinating techniques that allow your 3D file to come alive in multi-colour. Today the range of applications for 3D printers is becoming even more comprehensive. Whether you're a designer, a 3D artist, manufacturer, architect or hobbyist, this versatile technology can fabricate everything from anatomical models to desk toys to an array of consumer goods, figurines and even prototypes in colour. Colour 3D Printing can be divided into

- Direct Colour 3D Printing

- Indirect Colour 3D Printing

Direct Colour 3D Printing

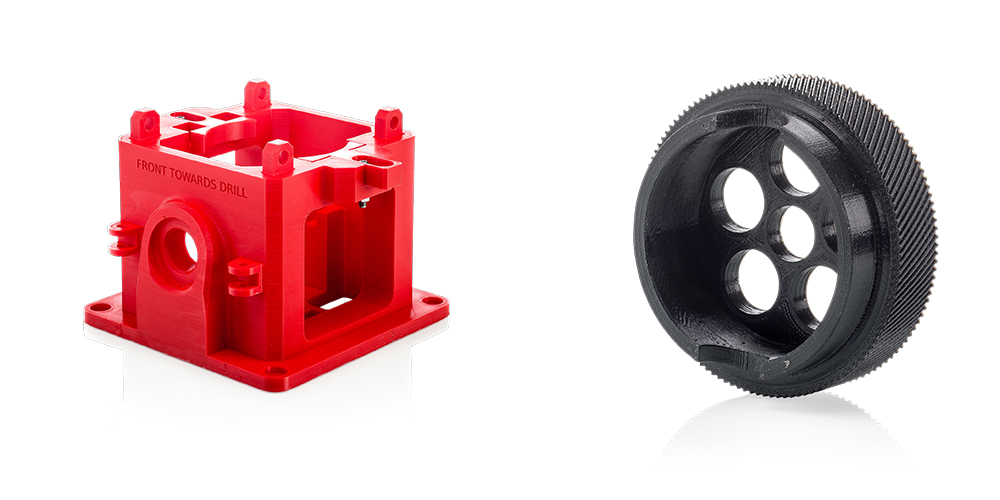

Direct Colour 3D Printing is done through the FDM (Fused Deposition Modeling). Here, a colourful filament is used to print your models. Bright colours and nice details are the results of high-quality filament. However, it would be a challenge to get a photo-realistic effect of your application as Direct Colour 3D Printing doesn't allow you to mix colours. This technology can be further divided into two parts based on the printer extruder.

FDM - Single Extruder

Wondering how is it possible to get colourful prints when the FDM 3D Printer has just one extruder? Don't worry, here's the solution. Once you are ready with your 3D files for printing, you need to set multiple tasks using the slicing software. The software would produce a G-code, which would instruct the 3D printer when to stop. This stop allows you to switch out the filament and the printing job can start again. This is a time-consuming and a bit risky solution as your model must have information about which sections would use which colour

PC: Imaginarium

FDM - Multiple Extruders

Today many companies have started using FDM printers with multiple extruders. A dual extruder was used for a long time to print dissolvable supports, but now many industries are using it to print two colours of filaments. Today, many devices are available with multiple extruders allowing you to print more than two colours.

PC: Ultimaker

Indirect Colour 3D Printing

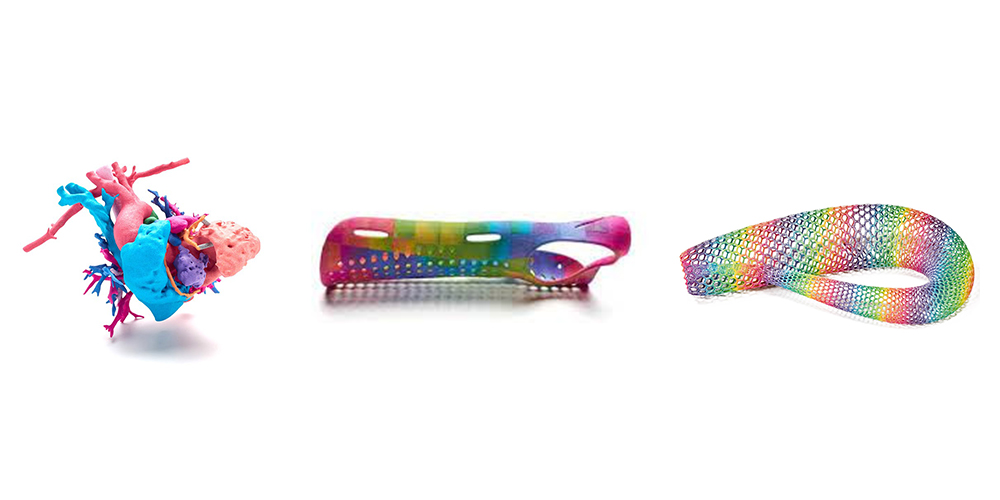

Indirect Colour 3D Printing is an industrial solution used for professional applications owing to the precision and realistic appearance of the 3D printed parts. Indirect Colour 3D Printing uses CMYK colour mode and therefore, professional knowledge is essential while opting for this technology. It is used primarily for prototyping, professional models and batch production. The three technologies that are used for indirect colour 3D printing are

PC: Imaginarium

Color Jet Printing

ColorJet technology has been around for over 20 years and is based on a very simple process - powder is bound by coloured glue. Fine, sandstone like powder material is used. First, the layer of material is spread, then the printing heads apply colour that adheres to the layer. Then the next layer is spread and the complete process is repeated. One of the most captivating things about the ColourJet technology is that it gives you a choice of colours. The post-processing process would include cleaning and anti-UV varnishing. The surface of the printed parts is coarse and porous and can even withstand temperatures up to 60°C. However, this technology is not recommended for parts that need a good mechanical strength or water resistance or even need to be ductile. Additionally, it is not suitable for transparent parts though it provides fair dimensional stability and value for money. Color Jet Printing is commonly used for figurines, anatomical models and non-functional prototype mockups.

PC: 3DSystems

Polyjet Printing

PolyJet technology uses liquid resin material and prints at an impressive 16 microns. It can be rightly said that it provides the highest resolution among industrial full-colour 3D printers. It assures fine detail and a smooth surface finish of your 3D parts. The colour is applied between the layers and cured with UV light. The post-processing would include support removal, polishing and UV coating. The parts printed through PolyJet printing technology can withstand temperatures up to 50°C. It has good dimensional stability, mechanical strength and an excellent range of colour choices. It is also perfect for printing transparent parts and provides a fair share of water resistance and ductility. One can easily use this technology for rigid functional parts as it gives a fair value for money. PolyJet printing technology is commonly used for functional and visual prototypes, transparent colour, glossy parts, anatomical models and figurines.

PC: Stratasys, 3D Systems, Mimaki

Multi Jet Fusion

The Multi-Jet Fusion printer uses an innovative binding agent to fuse the powder. The colour is applied at a level of 3D printing DNA called the voxel, a three-dimensional pixel. Today HP's Multi-Jet Fusion is the only technology that can print engineering-grade polyamide in full colour. The fairly new technology that hit the market in mid-2019 allows stronger prints that are less expensive than other full-colour solutions. The post-processing includes cleaning and sandblasting. It provides good dimensional stability, water resistance, ductility and a range of colour shades. Though this technology is not recommended for printing transparent parts, it can withstand temperatures up to 180°C and is excellent for printing rigid functional parts with mechanical strength.

PC: HP

Here’s a quick comparison that would assist in understanding the indirect 3D Colour printing features more effortlessly.

Features of Printed Parts | ColourJet 3D Printing Technology | PolyJet 3D Printing Technology | MultiJet 3D Printing Technology |

|---|---|---|---|

Surface | Coarse Surface and Porous | Smooth and Finely Detailed | Semi-smooth and Mild Texture |

Temperature | Up to 60°C | Up to 50°C | Up to 180°C |

Post Processing | Cleaning & Anti-UV Varnishing | Support Removal, Polishing and UV-Coating | Cleaning & Sandblasting |

Colour Range / Shade Range | Good | Excellent | Good |

Dimensional Stability | Fair | Good | Good |

Water Resistance | Not Recommended | Fair | Good |

Transparent Parts | Not Recommended | Excellent | Not Recommended |

Ductility | Not Recommended | Fair | Good |

Functional Rigid Parts | Not Recommended | Fair | Excellent |

Mechanical Strength | Not Recommended | Good | Excellent |

Value for Money | Fair | Fair | Excellent |

Disclaimer- the above-stated facts are in general and not guaranteed statements by Imaginarium.

What is your next colour 3D Printing Project?

3D printing technology is evolving continuously. Gone are the days when the 3D parts would be coloured in the post-processing stage by spray painting, dyeing or even hydro-dipping. There are plenty of opportunities for you to start using colour 3D printing. Right from FDM printers to industrial-grade machines, multicolour printing is the next wow in the manufacturing world. Do you have a colour 3D printing project in mind? Confused with which technology to choose or looking for the best colour 3D printing service for your application? Connect with us today.