Powerful 30W Laser

High Packing Density | Dense Build Chamber

Rapid Build Speed | Compact Footprint

Nylon (PA) Parts

Industry Realities: A Practical Stance

Due to the ever-increasing competition in today’s world, a lot of businesses struggle to stand out when it comes to achieving maximum customer satisfaction. Businesses relying on traditional manufacturing methods always have to compromise on one factor or another, such as build speeds, cost effectiveness, limited factory space, shortage of manpower, etc.

Formlabs, one of the most well-known additive manufacturing powerhouses across the globe, introduced the Fuse 1+ 30W, an SLS 3D printer designed to provide advantages to industries where speed is crucial while maintaining uncompromised product quality. Sectors like healthcare, engineering, architecture, aerospace, and defence fall under this category, among many others.

Accessibility Philosophy: Streamlining Integration

This stems from Formlabs maintaining a grounded philosophy, with far reaching impact: simplifying 3D printing for everyone, and their objective being to facilitate stepping up through seamless transition, catering to a diverse audience - from small businesses to industry experts.

The Fuse 1+ 30W: Practical Solutions

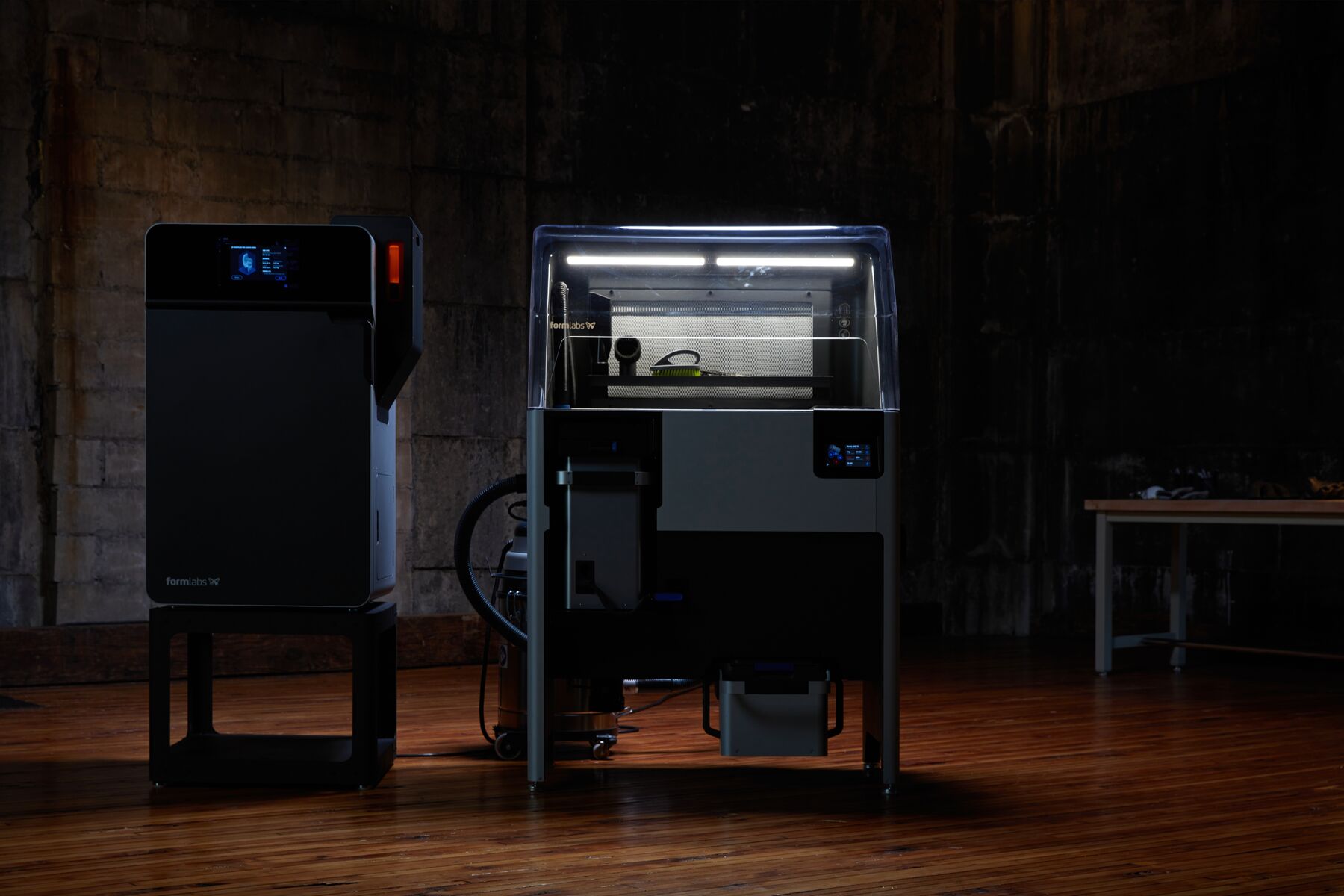

Utilising powder-based selective laser sintering (SLS) technology, the Formlabs Fuse 1+ 30W machine has been pegged as the ultimate optimiser - a machine that ‘maximises output while minimising waste’. Notable features include its compact footprint, dense build chamber and high precision 3D printing.

The main ideology behind the introduction of the Fuse 1+ 30W was to make 3D printing accessible to all, from newly operational service bureaus to well-established multinational conglomerates.

Compact Footprint

Upholding its reputation as one of the most compact 3D printers as compared to its competitors, the Fuse 1+ 30W has a recommended operating footprint of 49.4 x 59 x 66 inches (W x D x H), aiming to cater to smaller businesses that are tight on space, but high on ideas.

High Packing Density

Most 3D printers in the market have an average achievable packing density range of 10-15%. However, the Fuse 1+ 30W aims to one-up its competitors by offering a higher achievable packing density range of 20-30%. This high packing density critical as the higher range grants the ability to do more with less: print more parts during a single build, and in turn, reduce the production cost per part.

Dense Build Chamber

With a comparatively dense build chamber of 165 x 165 x 300 mm (W x D x H), the Fuse 1+ 30W was designed to help users build multiple items simultaneously, helping reduce overall time taken, expenses incurred and power consumed.

Rapid Build Speed

In an attempt to speed up rapid prototyping and small batch production, the Fuse 1+ 30W offers a build speed that can be as low as 15 minutes per part, and can print up to 12.5 metres per second

Powerful 30W Laser

The main source of inspiration behind the printer’s name is its 30W Ytterbium Fiber laser, capable of sintering powders strongly and relatively faster.

Header | Notable Properties |

|---|---|

Nylon 12 |

|

Nylon 12 GF |

|

Nylon 11 |

|

Nylon 11 CF |

|

TPU 90A |

|

Examples of a Few Applications

Header | Nylon 12 | Nylon 12 GF | Nylon 11 |

|---|---|---|---|

Jigs & Fixtures | Rigid, Impact Resistant | Stiff, Static, Load Bearing | Ductile, High Impact |

Enclosures | Balanced Stiffness and Ductility | Static, Mountable | Resilient, Pliable |

Air Flow Components | Not Suggested | Manifolds, Pipings, Ducts | Not Suggested |

Mechanical Connectors | Clips and Clamps | Threads, Sockets | Snap Fits, Sliding Joints |

General Parts | Balanced Stiffness and Ductility | Static, Rigid, Unyielding | Flexible, Resilient |

Fusing Solutions

Formlabs' introduction of the Fuse 1+ 30W, one of its best selling SLS 3D printers, stands as a practical response to manufacturing challenges. The discussion centers on understanding industry realities, promoting accessibility, and providing effective 3D printing solutions to all. As Formlabs addresses the complexities of 3D printing, the emphasis remains on sincerity and practicality.

The Fuse 1 machine is a powerhouse to create functional nylon end use parts which can replace injection molded components, when a short batch is required. The fact that Formlabs has eased access to an industrial grade technology which would otherwise cost upwards of 200,000USD is remarkable. This truly is one step towards bring AM closer to end use production.